Interview With James Thompson, AKA Black Badger

The watch industry, like its products, has a lot of moving parts. Millions of people around the world play their part in bringing our interest to life. But it is true that some people play a much more visible role in the task than others. Those characters that come to define eras of watchmaking should be championed. They should be listened to, learned from, and respected. Even if they did name themselves after a badger…

If you’ve never met James Thompson, you should probably stick it on your to-do list. I don’t mean in a creepy, stalker kind of way. I mean in a nice, dignified, organic kind of way (like “accidentally running into him” at an event). Please, please, please, do not board a plane for Stockholm and spend weeks traipsing around the Swedish wilderness looking for his isolated workshop. Firstly, that’s just weird. Secondly, anyone who has ever seen an episode of Wallander (in any language) knows that despite being a largely peaceful country, the grassy fields of Sweden are more deadly than Cabot Cove, Maine.

I first met James a few years ago at SalonQP in London. It was around the time of his collaboration with MB&F. The “Black Badger” name was hot property and, apparently, still is. In these contact-starved times, I caught up with the Badger a couple of weeks back via Zoom for a refreshingly honest and free-wheeling chat. Here’s the result of that talk for your amusement…

The interview

Rob Nudds: Right, I have to kick it off with a simple one. Where did the nickname come from?

James “Black Badger” Thompson: This is gonna sound really dorky, but when I first started making things myself I was a real carbon fiber nerd. I had this feeling I could make these really alien, funky Oakley-style things. I wanted something that had this Area 51 vibe. At the time, I was making more cosmetic parts for the paintballing scene and obsessed with making everything look “tacticool”. It was all night vision and stuff like that. Now it feels a bit silly looking back. As such, I wanted something a bit goofy, a bit “out there”, and something that had a kind of WWII squadron vibe to it. Know what I mean?

RN: Like the old US Airforce squadrons with over-the-top names like “Fighting Cocks”, “Lightning Lancers”, or “Flying Razorbacks”, for example?

JT: Yeah, that kind of thing. And I just kind of stumbled across “Black Badger” in my head and started sketching the logo in the margin of my workbook and thinking “Hm, yeah, that’ll do.”

And now, years later, I think it’s kind of hilarious that I’m working with these major Swiss companies and getting the chance to talk to all these luminaries of the watch industry and I’m just there with Black Badger emblazoned on my forehead. But, you know, I kind of grew into the name. Yes, before you say it, the beard is getting a bit grayer and I am probably looking more and more like a badger as time goes by, but I mean I came to embody the characteristics of a badger. They are plucky little guys. Tough for their size. That attitude has served me well. I wear the name — as tongue-in-cheek as it is — as a badge of honor.

RN: So you mentioned a workbook… I guess that means this career arc goes back a long way. When did you realize you wanted to dedicate your life to lume?

JT: Well, I knew I had to do something that challenged me. Working with new and interesting materials was always my thing. And yeah, you’re right, I took the leap back when I was studying. I just got so bored with everything. I packed up and moved to Sweden in 2002. Things were too comfortable back home. I wasn’t on the edge. I need to feel pushed to the edge to keep that edge that makes me sharp enough to survive in an industry like watchmaking.

It’s an established order. There are old rules and hierarchies all over the place. Breaking into that is one thing (I think being a bit ignorant of it helps to begin with). But breaking in isn’t the hardest part. It’s holding on to yourself once you’re inside that I think most people find challenging. It would be pretty easy to get swept up in it all and lose that special character that got you there in the first place.

Luckily for me, the stuff I work with (the materials themselves) is what gets me out of bed in the morning. It isn’t money, or status, or banging someone else’s drum. I like to do what I do and if other people get a kick out of it, then that’s cool by me. So I always knew I’d be working with this kind of stuff. The fact I found a niche in the watchmaking industry was just how things panned out.

RN: I guess it is great fun working with these materials. What are the best and worst things about it?

JT: You know, when I’m drawing I have a really hard time holding the 3D object in my mind. But I can do it with a physical object. So I kind of sketch in the material. It’s more like real-life 3D modeling. But I often let the material guide the way. When I make something straight from a design, it’s like watching a play that’s been rehearsed too many times.

RN: It loses its soul?

JT: Exactly. The material has to have its own character. It has to bring something to the design that can’t be planned or necessarily replicated. Its uniqueness is what makes it interesting. I’m just the middleman. My job is to bring the best out of it.

RN: I can see how that relates to your current project with Bamford very nicely, but before we get onto talking about what you’re doing right now, tell me about your favorite projects from the past?

JT: People ask me this a lot. And the answer changes on a daily basis. The watch I always reference when people ask me what I do is the MB&F. I loved the end result. And of course, if you recorded an album with Tom Jones, you’d tell people about it.

MB&F kind of handed me the keys to the truck. It was a joy. A coup. Max’s humility astounded me. He let me have a lot of input. And it was an amazing experience. It opened a lot of doors, but I had to be careful about which ones I went through. You know — you can only go so far up the mountain before you fall off the other side.

RN: Do you have any ideas when it comes to the watch movements themselves?

JT: (Laughs). I mean… I like them. They interest me. But I feel the same way I do about watch movements as I do about the game of basketball. I don’t want to get involved because I can’t do it myself. Honestly, in some of the projects I’ve been involved with, I couldn’t even name the movements.

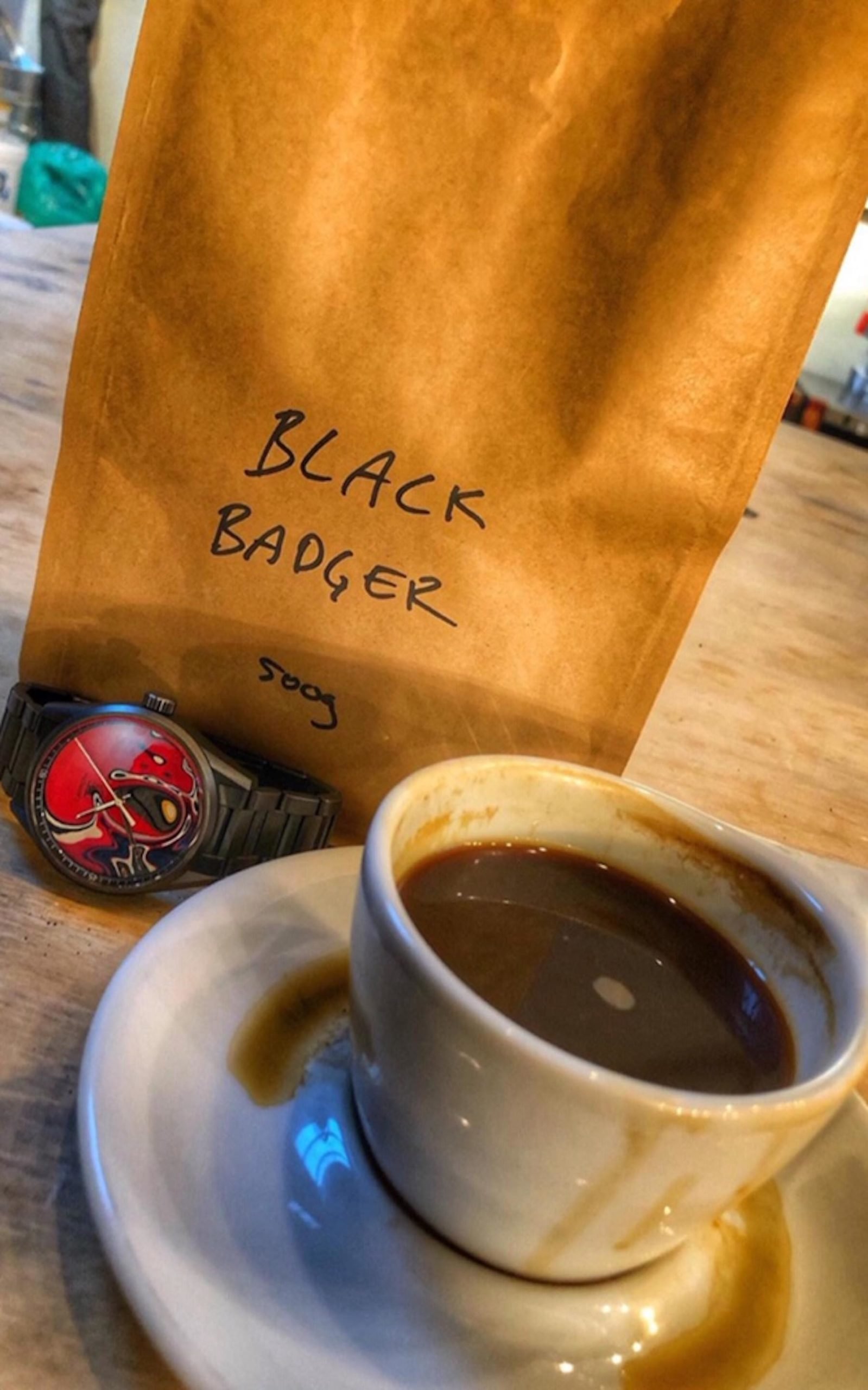

I’m not a watchmaker. I work in a very specific way. Black Badger is like a materials orphanage. I find new ways to use things that already exist. Like this sheet of coffee here, for example…

RN: A sheet of what-now?

JT: Coffee, man. You never seen a sheet of coffee before?

RN: I didn’t know it came in sheets…

JT: You’ve lived a sheltered life, Bobby. You can pretty much anything in sheets if you go to the right place. We actually worked with a roasterie to select the right blend of beans for color and so on. Not aroma. No one smells a sheet of coffee. You should know that before you go ahead and make yourself look stupid next time somebody waves a sheet of coffee under your nose. Don’t inhale. We mixed it with resin. And voila. Millable coffee…

It is difficult to do these kinds of things without becoming overly ironic. Or going way off base. But it’s important to experiment. Experimentation leads to the best discoveries, after all.

RN: I hope you don’t charge for segues because that was solid gold… It leads us nicely to your current project with Bamford. Tell us about it.

JT: So Bamford is best known for customizing existing designs. This project is a little different in that we are entirely remaking the dials for these watches. We’re making them from scratch from a material called Fordite.

RN: Fordite? Like the car paint used by Ford?

JT: Bingo. We’re using solid chunks of the stuff — nodes, we call them. The Fordite we used to create these dials is created from the overspray that collects around the cars as they are being painted. Over time, these layers build up like a sedimentary rock. And so you have this material with hundreds upon hundreds of layers of topcoat/clearcoat/primer, repeated over and over and over again.

At some point, some bright spark started cutting through it and discovered these amazing patterns. And it is real art. You have to be really engaged with the material. If you go ¼mm through the material the pattern changes entirely.

RN: it must be simultaneously exhilarating and heartbreaking…

JT: You bet. You have to have a lot of resolve to work with these over-sprayed nodes. You have to let it be. It’s important not to push it. You’re not in control. You never know what’s coming. It’s cool, but it can be excruciating when you go too far.

That exact pattern could never happen again. Each of those colors represents a car being painted in Detroit at the Ford plant. Those cars lived lives. They carried kids to and from school, families on holiday or to the grocery store. This is 4D art. When you cut through this material you are literally sanding through time.

The old paint Ford used to use had a load of solvents in it so when it goes through the oven it is hard as a rock. Modern paint is more water-based and a bit more flexible so that it’s less likely to chip and more likely to dent.

RN: What’s the most memorable pattern you’ve ever uncovered?

JT: Oh man, you’re killing me. Don’t make me relive this shit. I beg you!

RN: Something special?

JT: Something so, so cool. but ultimately devastating. I was working on this node, trying to get it down to the right level of thickness so it could be fitted into the case. And suddenly, the Apple computer logo from the ’80s appeared. It was like a vision. It was biblical. I wanted so badly to stop, but I had to carry on sanding. I took a photo of it, which I still have somewhere but can’t bear to look at it. It was the damnedest thing. Four or five strokes of the sander later and it was gone.

RN: It brings a tear to my eye…

JT: Yeah, that was about as bad as it gets, but there are other frustrating things to contend with. Remember, this shit was never intended to be used for art. It is a waste product. So people never took any care in making sure every layer is nice and smooth. Sometimes you get inclusions like masking tape from 1978. And there’s nothing you can do. You have to dig it out project falls to bits. You can be working on it for hours and then BAM. Some fifty-year-old tape laughing at you. The Bamford project feels very much like a discovery. A mutual discovery. I’m enjoying it a lot.

RN: What are you wearing right now?

JT: Right now I have this badass creation from MW&Co. on my wrist (check it out above and below). It’s exactly the kind of project I live for. It makes the most of the luminous compounds that I’ve made central to most of my work. Consequently, it looks like it just landed on my wrist after a long trip through Space. It doesn’t get much better than that. This model is the limited edition MW&Co Asset Black Badger and it will be available soon. Check out the website for more info on it and the brand. I think it’s a match made in heaven.

RN: Last question for now (although we should definitely do this again sometime): give me an example of a project you didn’t work on, but kind of wish you had…

JT: Ha! Remember that Swiss Cheese watch from H. Moser & Cie? That was nuts. I loved it. Totally mad. But totally on-brand. Those guys have a great sense of humor. I had nothing to do with it, but I would have enjoyed that one. It’s cool to see an elegant brand like Moser do funky shit like that. I could imagine working with them. I think working with a brand that produces really elegant watches is a step I’d certainly like to take. But who knows what the future holds…

This interview was conducted on June 1st between Rob Nudds of Fratello and James Thompson of Black Badger.

Follow me on Instagram @robnudds