You Asked Us: Why Does It Take Limited Editions So Long To Be Delivered?

Even today, when writing this article, I received a note from someone asking why it is taking so long for his ordered limited edition watch to be delivered? It is a question that pops up frequently in our conversations and inboxes.

And believe me, I know how it feels to wait for a (very) long time on that watch you ordered. In fact, you want it the minute you made the deposit or paid the full amount. But there’s little you can do. You need to wait till it is produced and shipped. My first experience with this phenomenon was a Linde Werdelin 3-Timer back in 2009. I ordered it during Baselworld of that year, which was probably in March or April, and I had to wait until November before it arrived. It was something I never experienced before (I think it was my first LE) but I’ve had many similar experiences since.

Limited Editions — The Wait

Now, as you probably know, we’ve been on the other side of the table as well. The Omega Speedmaster Professional Speedy Tuesday models, for example, had our involvement. Or more recently, the Oris Big Crown Pointer Date in bronze and the Minase Divido. Here we have three very different brands, but many of the takeaways are the same. We’ve been lucky enough to be in the “kitchen” with them to see how it works when you are designing and developing a watch. In this article, I will share some of those experiences with you, to shed some light on the process of developing a limited edition.

The interesting thing is, the brands we collaborated with for our shop, are all very different. From a very small and niche Japanese brand to one of the largest Swiss watch brands in the world. From a handmade, artisanal product, to a completely industrialized manufacturing process. This also gave us the opportunity to see how each of them operates, and how different they are from one another. Experiencing the challenges they each had to face, during the process firsthand, was illuminating.

Speedy Tuesday experience

Creating a limited edition, often means that the watch brand needs to do things differently than they are used to or need different parts. The Speedmaster “Speedy Tuesday” models “Tribute to Alaska III” (ST1) and Ultraman (ST2) were quite different from the regular Speedmaster Professional. The dial of the ST1 had a special varnish and the hands were brushed. The case was identical to the one of the Moonwatch, but with a brushed finish and a different engraving on its case back. The ST2 had the regular case, except for the case back, but with a special bezel with “Tachymètre” printed in orange and with the return of the famous — to Speedmaster enthusiasts — Dot-Over-Ninety scale. The dial is made of aluminum (a first for the Speedmaster) and has the famous “step”.

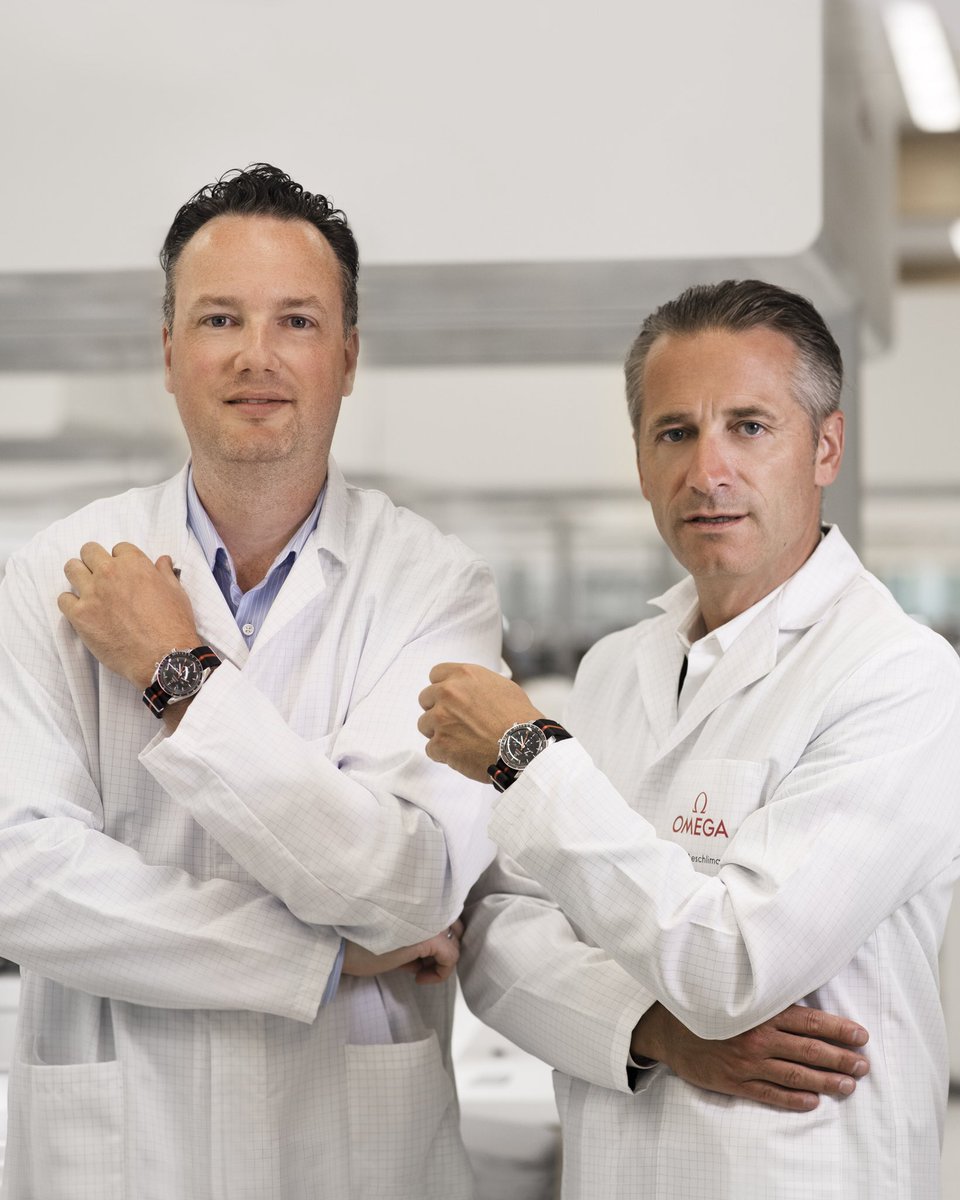

Omega CEO Raynald Aeschlimann on the right and yours truly on the left, during the introduction of the Speedy Tuesday Ultraman

Samples and checks

All these things weren’t in other Omega watches, so they needed to be manufactured from scratch. Now, Omega works closely together with a number of (Swatch Group) owned Swiss suppliers. That means that getting specific or custom parts can be done in a relatively timely manner. For every part though, you want to have a sample or prototype, to check if the quality is as expected, whether it looks good (or not) and if the colors (if applicable) match what you had in mind. The Speedmaster Speedy Tuesday watches went into production after the introduction. This means that it took a few months before the first ones were ready to be shipped. For some, the wait was longer than for others, and eventually, it took up to approximately a year after its initial introduction in January 2017 (although the delivery started in June that year).

Of course, the run size of the Speedy Tuesday edition also played a part. With both releases, we release 2,012 pieces. That is a lot of quality control and a huge manufacturing undertaking that could be interrupted or downright halted during the projected timeframe. Ironically, perhaps, in this regard, small, artisanal brands have an advantage in that they are more immediately flexible on a micro scale. However, when the ball gets rolling with one of the industrialized giants like Omega, it is a thing of beauty to behold.

Fratelloris Experience

The Oris Big Crown Pointer Date in bronze that we did together with the brand from Hölstein is another good example. For this watch, the case was an existing element, but we wanted to use a (burgundy) red dial. A red dial was available for the steel version, but we decided we wanted to have gilt elements on the dial to match the bronze case. Also, we wanted different wording on the dial. Oris is not a small watch company for sure. However, the brand does depend on suppliers to produce and deliver those new parts.

Before the dial production can start, you want to make sure that they are going to make exactly what you want to have. And colors, printing, etc. can always look different from mock-up images, so you’ll need a sample or prototype first. When the sample is approved, the dial manufacturer can start producing. The Oris Big Crown Pointer Date in bronze with a burgundy red dial, or “Fratelloris” as some call this watch, was introduced in December 2020 and we started shipping the same day.

Available immediately

However, that doesn’t mean the process was quicker than with Omega. On the contrary. The talks, but also the moment we decided on the dial color, printing, straps, box (the red box was also a custom job for our watch), etc. took quite some time. The time from the final decision to the actual delivery was planned to be around nine months, but, due to Covid19, it took a bit longer. In the end, we decided that we didn’t want to introduce the watch, take your orders and then start production. We wanted to have the watch available at the time of introduction, so there would only be the shipping and handling (3–5 business days) separating ordering and delivery. We are watch collectors ourselves, so we know how annoying the wait can be.

Production and Planning

So, you see, the main issue with limited editions is the production and planning. As soon as you want certain parts to be different, it influences the production capacity and planning. As with most things, the exceptions consume the most time and effort. Not only for the suppliers who need to manufacture these parts, but also a lot of time is lost in the checks, discussions, and decision-making.

The crucial question, of course, is when this phase takes place. With bigger brands that rely on being able to schedule everything in advance, it is quite possible this phase occurs later. Perhaps even after the watch has been released. For incredibly complex artisanal projects, also, this phase is likely to be later once the orders are finalized. For a special edition to have been signed, sealed, and delivered before it goes on sale requires a special cocktail. Generally, it requires money, faith, and manufacturing capacity. With the Oris project, we had that. As such, it was our quickest delivery so far. We are learning constantly. The more we work with brands behind the scenes, the more we understand the limitations.

Having these experiences will help us in the future. We don’t just want to make awesome watches; we want you guys to enjoy the process with us! The delivery timeframe is something we’d like to keep as short as possible. However, having hung around behind the curtain for a while now, we know it isn’t always possible. It’s a lot easier to deal with waiting now than it used to be. Knowing the kinds of things that can slow the process, really helps.

Quicker Deliveries

What we see today, is that the demand for watches is high anyway. Well, at least for some of them. Regardless of whether they are limited or special editions or just regular collections, there seems to be more demand than supply. Some limited editions, just take longer to manufacture. This was the case with the Silver Snoopy Award from 2015. The case back was done by hand. I think they could only do three a day of those. Also with the new Silver Snoopy Award 50th Anniversary. The solid silver dial takes quite a lot of time to produce and the automaton on the reverse is something else! However, in this case, Omega already started to deliver early on. The fact that you don’t have yours yet, has to do with a combination of high demand and slow production.

Clarity

In the end, if you truly love a limited edition watch, the wait might be long, but worth it. If you’re into it for the short win (whether that’s showing off you’re first, or if you want to flip it), the wait is perhaps just annoying. I don’t mind the wait to be honest. Of course, I prefer it to be reasonable, but it is almost part of the fun. And remember, the brands are in the same boat! It can be as frustrating for them as it is for you.

What for me is more frustrating is clarity. Can you get the watch at all? Even when you did a deposit? It is not always a given that a deposit will lead to the allocation of a watch. At least when you get an allocation you know it is coming at some point. Waiting for something that will never arrive is dreadful.

What was your worst wait? And what was your best delivery experience? Share those things with us in the comments below.