Making A Case For Watch Refinishing — See How The Pros Do It

Refinishing is a topic of debate. Some say you should never have a watch refinished. Others have their watches touched up with every service. Few people realize, however, that refinishing is a craft that takes great skill, so there is a big difference from one refinished watch to the next. I thought I would meet up with our friends at Tempus to see how it is done.

Mark from Tempus was generous with his time and knowledge, sharing the entire process with me. He redid the surface finishing of a fairly hard-worn Rolex Explorer 114270. Let’s see how it is done and what it entails.

Refinishing: yes or no?

In my vintage-dealing days, the subject of refinishing was a source of much debate. A vintage watch with its original finish intact is considered highly desirable, so beginner aficionados often demanded unpolished watches, woefully unaware of what that actually meant. Completely unpolished vintage watches are rare. And you have to ask yourself whether you actually want to wear such a watch. We have to make a distinction between ultra-rare collectible watches and those for everyday wear.

The problem people have with refinished watches is that they often lose their shape and proper surface textures. And that happens because dealers and lesser watchmakers just polish watches without the required practice, experience, and equipment. They take away too much material and lose the lines of the watch in the process.

If you ask me, there is nothing wrong with touching up a watch now and then. It just has to be in keeping with the watch. To me, a heavily patinated dial and bleached bezel do not pair well with a razor-sharp restored case. But what if you fall off your bike and scrape your nice watch? There is no need to live with that painful reminder if you know a proper craftsperson.

Refinishing a Rolex 114270

Okay, with that out of the way, let’s get into how it’s done. Tempus is a Dutch watchmaking atelier run by Mark and Jasper. They have recently become an authorized Cartier service point, which included extensive additional training in refinishing techniques. They were willing to let me in on their secrets as Mark demonstrated the process. There was a Rolex Explorer ref. 114270 in for service, and the case had seen better days.

As you can see from the picture, the case is full of small dents and scratches. This Explorer has clearly seen some hard wear. Some people would certainly be fine with an aesthetic like this. However, this watch revision was commissioned by a dealer who will put the watch up for sale, and the vast majority of potential buyers prefer a nice, clean case. Work had to be done!

Step 1: Removing scratches and dents

To understand the process, we have to break it up. The term “polishing” is often used to describe the entire refinishing process. In fact, it is only the application of a high shine to the desired surfaces. If you polish a scratched surface, you will end up with a shiny scratched surface. Thus, the first step is to clean up any damage.

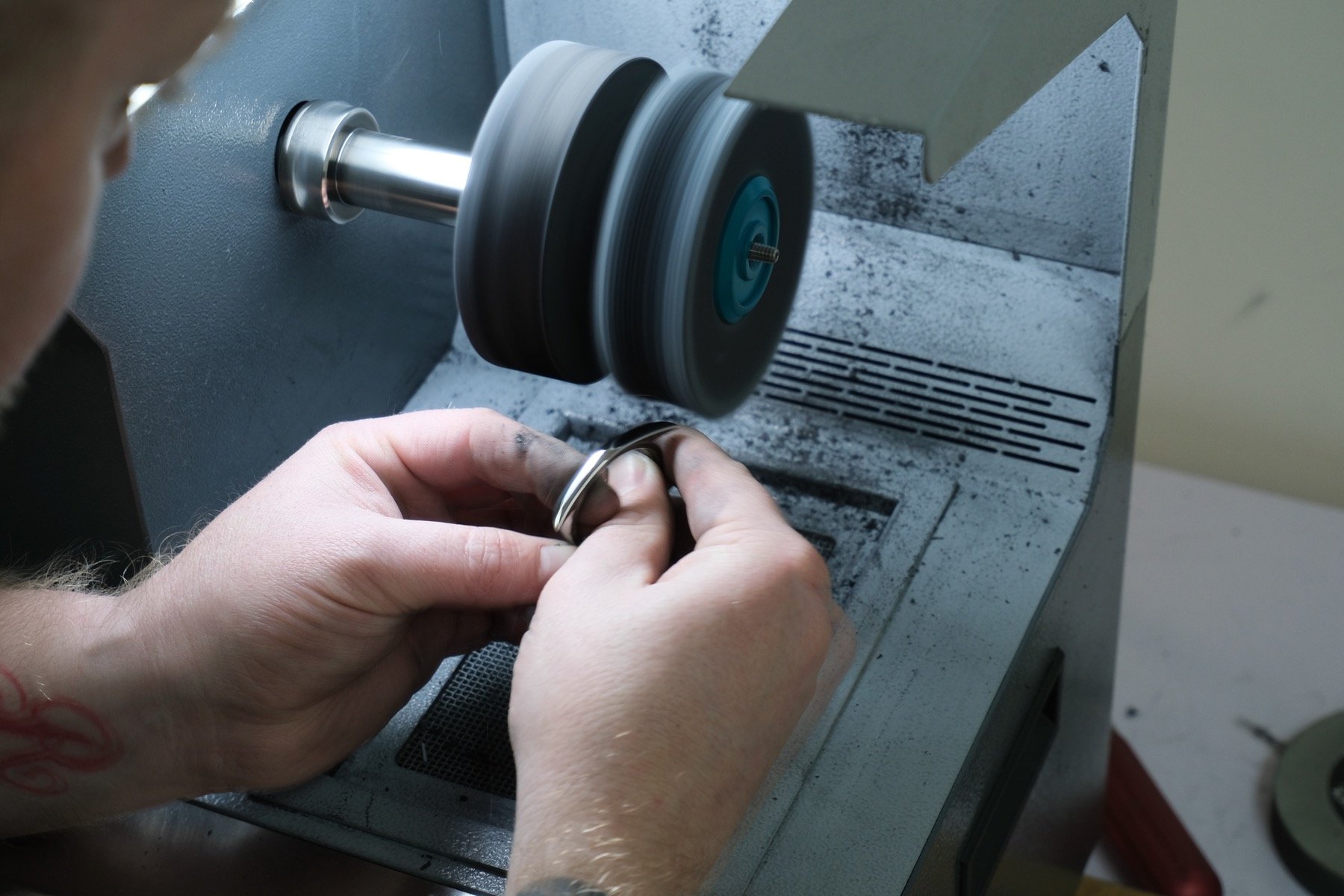

The Explorer’s case does not feature any truly flat surfaces. As you may know, the flanks of this Oyster case are sort of bulbous. This means the lapping wheel is out of the question. Mark uses abrasive wheels on a pretty standard polishing machine for the process.

This is where the craftsmanship comes in. Mark tells me, “You always have to keep moving. Otherwise, you get flat spots.” He has a finely honed technique of smoothly running the case along the spinning wheel and constantly bringing it back up for visual inspection. You want to remove as little material as possible, hence the constant checking. His quick movements seem not to affect the case’s shape whatsoever. Having dabbled in silver smithing myself, I know for a fact that this is hard to do.

Step 2: Applying a high polish

This may seem counter-intuitive, but the polish is applied before the hairline finish is cut. It makes sense, actually, as the hairline finish gives a hard edge, whereas the polishing wheel leaves a vague transition. So if you want a razor-sharp line between your surfaces, there is only one way to do it.

Mark uses a second wheel comprised of layers of fabric discs. They are packed tightly together to form a soft running surface that he lightly brushes with a polishing paste. “It is tempting to use too much polishing compound, but the result will not be as good,” he explains. Mark actually scrapes the wheel clean before applying a tiny dab of the compound. There are many different compounds for different materials and different finishes. The specific compound chosen is often personal to the individual watchmaker.

The rhythm of smooth passes and visual inspections repeats. The polishing machine is set to a very low speed to prevent heat from building up. If it gets too hot, the steel will turn foggy, which takes great effort to clean up again. Within no time at all, a bright, mirror-like surface emerges. Next, the case goes into a shaking water bath to remove the grease and any residue.

Step 3: Cutting the hairline finish

The hairline finish — or brushing — is applied last. This step is very hard to get right. I have seen so many lugs with flat spots in my days and even more cases with the wrong depth and “resolution” of brushing. They often end up a little too cloudy or even a little shiny. You want a straight, sharp, and pronounced texture.

There are several ways of doing it. The boys at Tempus have experimented a lot and ended up with a method that reliably produces the right surface. This is, however, a bit of a master’s signature, so they asked me not to disclose which method they use.

What I can tell you is that it is very much a manual process. If you were expecting laser-guided robot arms to brush the surface at the perfect angles, you would be wrong. The precise contouring of the lugs, the direction of the brushing, and the levelness of the finish are all done by hand. It takes another confident and smooth sweeping motion to do it.

Refinishing flat surfaces

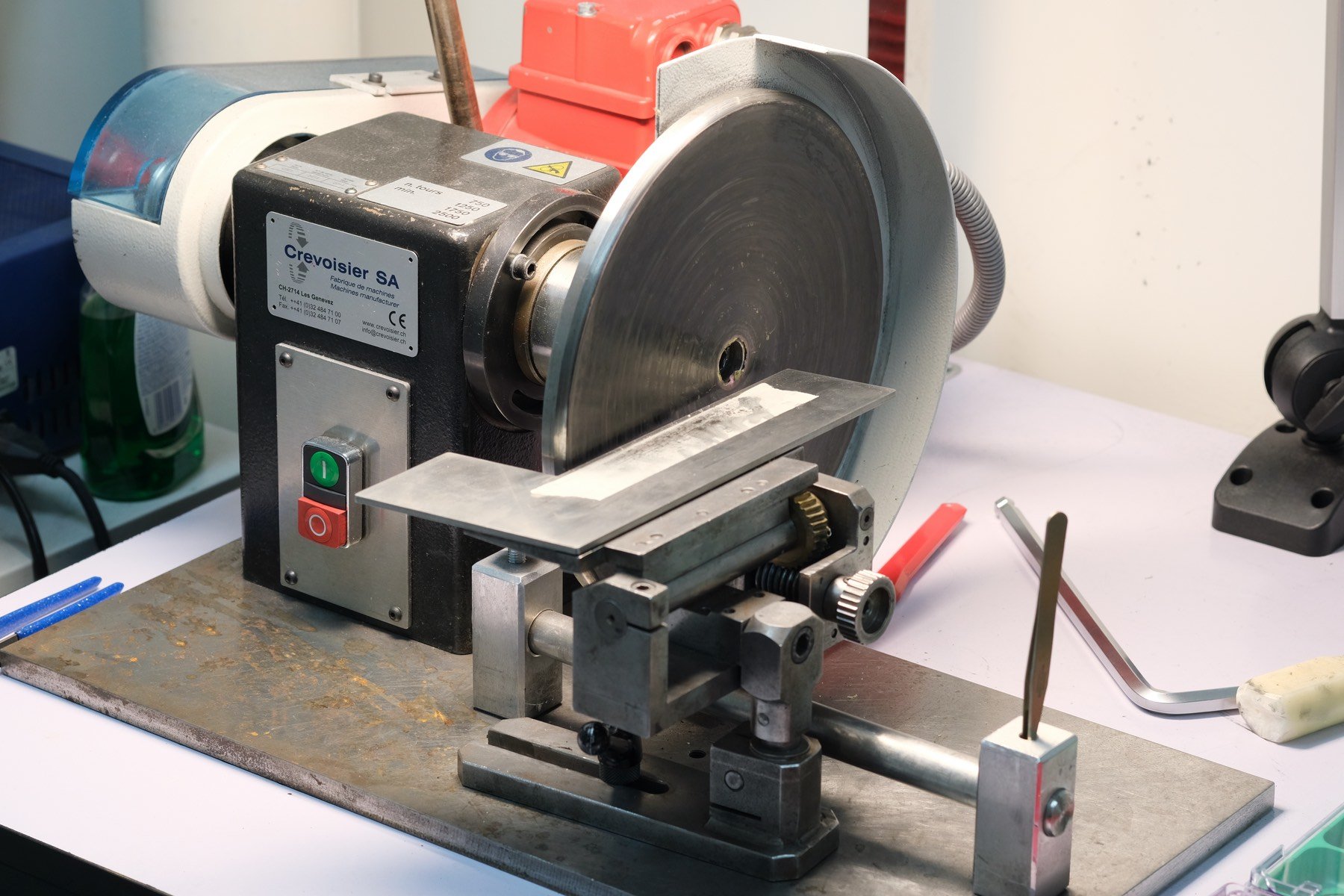

Next, Mark showed me a case that was curved along one axis but perfectly flat along the other. “If you use the same method on this case, you will round off the flat surface and edges,” he explains. This is where the lapping wheel comes in.

This machine features a perfectly flat rotating abrasive disc and a rail for attaching a table or a faceting mount. Here, you use the flat side of the wheel rather than the running surface. Mark sets the right angles to ensure the flat side of the case is perfectly parallel with the wheel. Then, it is once again a matter of very smooth sweeping passes along the surface.

The lapping wheel ensures flatness and hard angles that soft wheels could never replicate. I have seen plenty of sports Rolex watches with rounded case flanks. The wrong tools for the job are the culprit.

Closing thoughts on refinishing

Although I had a pretty good idea of what case refinishing entails, I was still surprised about the level of skill involved. You need quite a lot of knowledge, but it takes physical practice too. Like playing a musical instrument, you have to know what notes to play, but you also need muscle memory to play the notes with clarity and groove.

Whether you want your watch refinished is up to you, but I would urge you to have a close look at before-and-after pictures of your prospected watchmaker’s work. There really is a fine line between a ruined watch and a beautifully restored watch. If done properly, the amount of material removed is kept to a minimum. This means you can do this a few times during a watch’s lifespan. I would also advise you to discuss the details. If your case features beveling, ask if the watchmaker can put that back on. You would not be the first to receive your watch back sans the bevels.

I want to express my thanks to Mark and Jasper from Tempus for showing me their process. It was very cool to see a battered Explorer return to its former glory. Its next owner can put his or her own battle scars on it. The boys will be ready to clean it up again if he or she prefers it pristine.

I would love to hear about your experience with refinishing in the comments below. Have you had any particularly good or bad examples while servicing your collection?

You can also find and follow me on Instagram: @time_travelers_journal