Making The Case For Case Finishing: What Separates The Good From The Bad? — Examples From Seiko, Hamilton, And Minase

The finishing quality of a watch is one of the major determining factors in how that watch looks and feels. The term is thrown around all the time but seldom explored. Prices are often justified or criticized on the basis of finishing quality. I am talking about case finishing in particular here — the way the surfaces are polished, brushed, and beveled. If you have not had the privilege of handling a lot of watches, you may not have an intuitive feel for what that actually means. So in this article, let’s have a closer look at case finishing.

I will try to cover some of the challenges brands encounter and some of the techniques that they use. I will also aim to share some examples of case finishing at different levels. Let’s get stuck in!

Levels of complexity in case finishing

The first element of significance here is the complexity of the case design. You can make a case with soft, rounded shapes that is completely polished. That is a lot easier than combining brushed and polished surfaces, especially if those surfaces are made up of compound curves. This is why watches in the lower segments usually have simpler shapes. It is not the shape itself that is necessarily tough to make at a lower cost. Rather, it is the finishing that would push the price too high.

Still, the level of complexity tells you nothing about the actual quality of the finishing. You can, of course, poorly finish a complicated case. You can also apply great finishing to simple cases. My personal Grand Seiko SBGW231 is a prime example. Its case is soft and simple. Still, the entire thing is polished to a perfect mirror-like surface, which takes time, skill, and effort.

But how do they do it anyway?

You may be surprised to learn that a lot of surface finishing is still done by hand. Some shapes can simply only be polished or brushed by hand. That, of course, leads to a certain degree of inconsistency that is characteristic of artisan handwork.

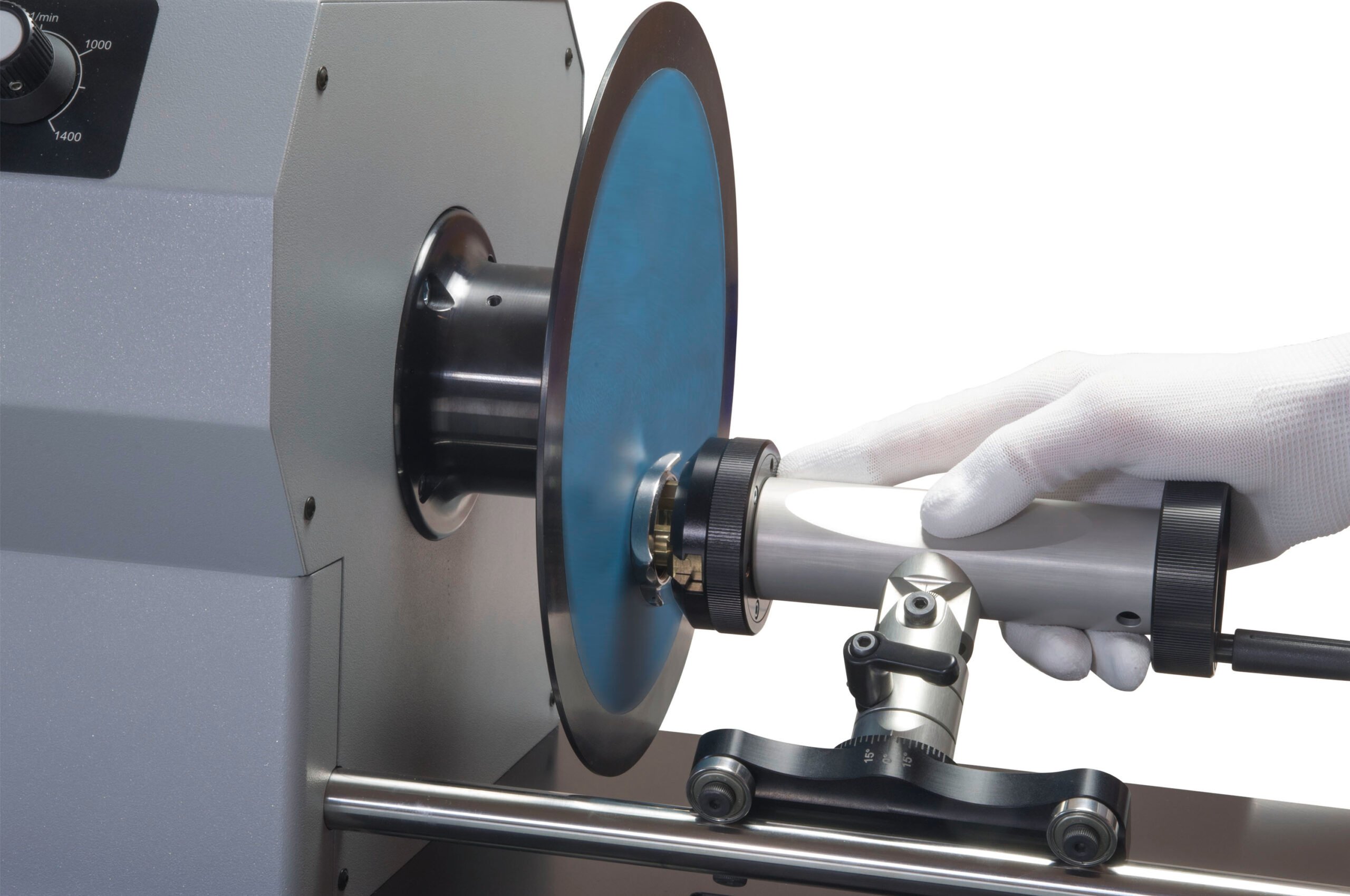

A lot of case surface finishing is done on a lapping wheel. A motor powers an upright disk that is perfectly flat. The type of finish accomplished is determined by the surface of the wheel. The operator can manually hold the case up against the wheel. Otherwise, a faceting arm can be used. This will keep the case at a precise angle across multiple axes. It can also allow for movement across a single axis for a very precise, curved surface.

Many modern watch manufacturers use a robotized version of a similar setup. The perfect repeatability has to be weighed against the lack of an artisan’s sharp eye. Of course, combinations of robotized and manual finishing can be utilized as well.

A word on Zaratsu, Sallaz, mirror, and black polishing

You may have heard some of these terms to refer to specifically excellent levels of case finishing. Zaratsu (ザラツ) is a Japanese transliteration of Sallaz. Its origin is the acquisition of German Gebr. Sallaz polishing machines by Seiko in the 1950s.

The main technical difference with traditional polishing is the use of the flat face of the polishing disk, rather than the round side. If the polishing wheel were a car tire, you would not hold the case against the running surface, but against the sidewall (as pictured on the image of the lapping machine). As you have read above, that is actually not entirely uncommon. But for truly impressive results, you need to combine the technique with a greater number of passes with increasingly fine polishing compounds, cleaning the case between every step. The end goal is a perfect mirror-like surface. Zaratsu is, in this sense, a dedication to a higher standard rather than a unique technology.

Mirror polishing and black polishing are essentially the same things as Zaratsu/Sallaz. The difference is that black polishing usually refers to smaller parts, such as screw heads. The name is derived from the fact that, at a certain angle, such parts appear black. The method used is of lesser importance for the terminology. It is the specific aesthetic of such parts to which the term “black polished” refers.

Entry-level case finishing: Seiko SKX

So much for theory. Let’s have a look at some close-ups to see what this all actually entails. I have picked three watches with finishing worth examining. Above, you see a macro shot of the lug of a Seiko SKX. As beloved as the SKX is, it is also notorious for its poor case finishing. Note: this example is well worn, so the fine scratches were added by yours truly.

For starters, you can clearly see that the shape of the lug is quite soft. You will even spot a bit of a wobble if you follow where the chamfer converges. Next, look at the actual brushed surface (also referred to as hairline finishing). It does not reach the ends of the top facet of the lug. It looks as if the lug has merely kissed the brushing wheel, leaving its perimeters glossy. This makes sense, as brushing is usually done after polishing.

Looking closer at the brushing itself, you can see it is quite shallow. In fact, you can still see a reflection of the bezel on the top of the lug. This means the previously polished surface still shines through the brushing. This indicates that the finish is extremely shallow. You may also spot that the hairlines are not all perfectly parallel. This all leads me to believe the brushing was done against the running surface of some sort of steel-wool-like wheel.

Mid-segment case finishing: Hamilton Khaki Pilot Pioneer

Now, before I get started with this example, let me say that I am not here to shame Hamilton. The Khaki Pilot Pioneer is a re-edition of a historic military reference, so it is obviously not trying to be a luxurious piece of jewelry. Its level of finishing reflects that. This is still a very cool watch that I would wholeheartedly recommend. It is, however, also a very good example of poor finishing in a slightly higher segment. In this segment, the variance in finishing quality is pretty big. You will find SKX-like finishing as well as superb finishing in the €500–2,500 range.

First of all, look at the altogether wonky case shape. The tip of the lug really drives this point home. The chamfer along the flank is another giveaway. Rather than a sharp razor-edge, it is wobbly and uneven. The brushing of the top and side of the case bleed into the chamfer as well.

You can also spot a pretty clear reflection of the table underneath on the flank of the case. Again, this indicates a very shallow finish. It is certainly more pronounced than on the SKX, but it is still shallow. This is confirmed by handling the watch. It feels very smooth and pebble-like. A good hairline finish has a grippy, tactile surface. You can actually feel the individual cuts that make up the brushed finish. That is not the case here.

High-end case finishing: Minase Divido

On to an example of very good case finishing. Above, you see the Minase Divido. Minase uses Sallaz polishing on its watches, and it clearly shows. Before we dive into the finishing, it is good to realize that this is a very complicated case shape. So not only does Minase hold itself to a high level of finishing, but it does not necessarily make its own life easy along the way.

Have a look at that chamfer. It is razor-sharp, parallel, and perfectly black-polished. It offsets a truly flat top facet of the lug. The inward-angled, brushed side of the lug is similarly flat. But have a look at how it then smoothly bends into the tip of the lug. That is brushing along a compound curve, without any flat spots or visible imperfections.

On to that flat top surface. It is perfectly matte, with none of the vague remaining reflections we saw earlier. The hairline finish is deep and pronounced. The surface feels slightly grippy, sticky even. It is the sign of a brushed finish well done. You can also see how the hairlines run perfectly parallel.

Closing thoughts

I hope these examples provide you with an idea of what we mean when we speak of finishing quality. When it comes to case finishing, you do not always get what you pay for. There are very affordable watches with very decent finishing. At the same time, you will find mediocre finishing on very expensive watches. I must also say that it is not always completely relevant. A military tool watch might actually look better with rough finishing. It makes more sense conceptually.

It is, however, easy to underestimate the impact of case finishing on the overall feel of a watch. You may have experienced that “wow!” sensation when you picked up a particularly good watch. There is a good chance it had something to do with case finishing. It is one of those ingredients that can lift a watch from ordinary to awe-inspiring.

Which watches have you experienced that have particularly excellent case finishing? And which were underwhelming to you? I am curious to read your answers in the comments.

You can also find and follow me on Instagram: @time_travelers_journal