A Tour Through Louis Vuitton’s La Fabrique Du Temps In Geneva

Two weeks ago, Louis Vuitton launched its all-steel, fully made-over Tambour. It’s a watch that shows how serious the Parisian Maison is about its horological ambitions. According to the comments below the introduction article, some people still have to get used to the idea of wearing a watch that says “Louis Vuitton” on the dial. Well, maybe this report on my visit to La Fabrique du Temps, the brand’s home of watchmaking, can help convince those people. And for everyone else, it can simply be a nice peek inside the brand’s watch kitchen. In any case, here we go.

The morning after the day of the presentation of the new Tambour at Musée d’Orsay in Paris, we took a high-speed train to Geneva. La Fabrique du Temps is located in Meyrin, a municipality on the northwest side of Geneva, almost right next to the city’s airport. It’s an area where a lot of horological activity is going on. On the way there, we passed the Roger Dubuis offices and Richemont’s Campus Genevois de Haute Horlogerie. And from the windows of the Louis Vuitton watch factory, you see the Chopard headquarters right next door. So it’s not entirely coincidental that the facilities are in that area.

La Fabrique du Temps and Louis Vuitton

It wasn’t Louis Vuitton, though, who founded La Fabrique du Temps. That was the work of Michel Navas and Enrico Barbasini, who, in 2007, wanted to create a place where technical craftsmanship and artisanal savoir-faire could come together. The two master watchmakers and their team developed watches and movements for brands like Jacob & Co, Speake Marin, Laurent Ferrier, and Louis Vuitton. In 2011, LVMH decided to acquire La Fabrique du Temps. Since then, Louis Vuitton watches like the hand-painted Escale Worldtime, the incredibly bold Tambour Carpe Diem, and the sporty Tambour Street Diver have all been developed there.

That building in the back, behind the Chopard headquarters, is the additional office space, allowing even more disciplines to join the operation.

Almost all the disciplines necessary to build an entire watch from scratch are gathered at the manufacture. Although, for the new Tambour, a few parts, like the movement and the case, were still manufactured externally. Louis Vuitton did so in close collaboration with Le Cercle des Horlogers, located south of La Chaux-de-Fonds. But just a block away from La Fabrique du Temps, the brand has already acquired more office space. So in the future, it will be possible to manufacture almost an entire watch in-house. It will still take a few years, but again, it’s clear that LVMH is serious about its watchmaking ambitions.

A completely new focus

To reinforce that, Jean Arnault, Marketing and Development Director at Louis Vuitton Watches, even made a bold statement at the launch of the new Tambour. He announced that 80% of the current watch portfolio would be removed from the range. And the watch section of the Louis Vuitton website confirms that statement because, right now, you can only find mechanical watches and high-horology pieces there — apart from the connected watches. That means a lot of quartz watches had to clear the field.

So it does look like it wasn’t just a bold statement but that the brand is focusing on more serious watchmaking now. We also asked about it during the tour through the facilities, and employees told us that most of those “retired” watches will soon be used only for their spare parts. Again, it seems like a very bold move. But it needs to be done when you’re aspiring to become one of the greatest watchmakers in the industry. All right, enough introduction, let’s take a look at the facilities.

First stop: the QC department

After we put on our blue Louis Vuitton robes, we were ready to enter. Right around the corner was the quality-control department. This is where all the parts and assembled watches are tested. They showed us a device with which the crown is pulled out and pushed in again. It reminded me of the machine at Ikea that tests the endurance of the brand’s famous armchair. Another important thing is measuring the accuracy of the movements, especially since the new Tambour is certified by the Geneva Observatory to run within the chronometer standards of +6/-4 seconds per day.

A lot of the LV employees there were wearing the new Tambour. I don’t know if this was specifically for our tour, but it seemed like the people there were proud of their new product. It was even already hanging on the walls of some of the offices. Of course, the QC department is essential, but it was also the least exciting to see. So let’s move on to a more exciting department where they work on those beautiful artistic dials.

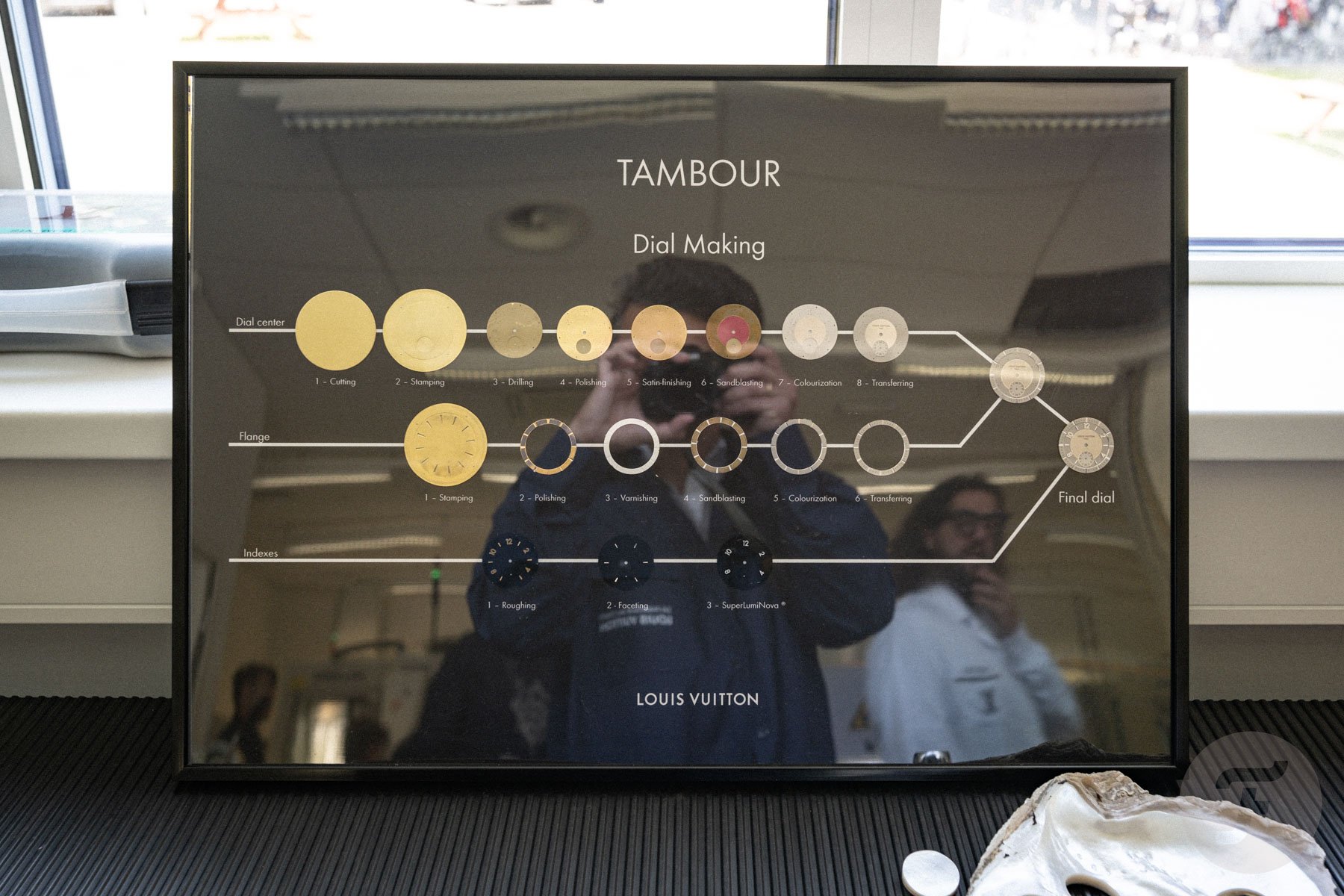

Next up: The art of dial-making

We stepped into a small and relatively dark room. In it were four artisans finishing the most beautiful and complex dials. We couldn’t take many pictures because some pieces they worked on still needed to be unveiled. Luckily, the head of the department, fellow Dutchman Dick Steenman, was working on the Tambour Einstein, which was just revealed for the Only Watch Auction in November of this year.

At the end of the room, we went through another door, which led us into the space where the dials were being made. We looked at how many steps and materials are involved in creating one dial. It’s impressive, for example, to see that so much work is put into creating the dial of the new Tambour. It makes you appreciate the craftsmanship that goes into those little machines you wear on your wrist every day. And that feeling got even more palpable as we stepped into the room where they painted the dials.

That was especially because we got the chance to manually paint the dial of the Escale Worldtimer. You know, that watch with the 38 colors all around the 24 cities you can find on the dial. It usually takes 40 hours to apply the acrylic paint onto that dial with a very steady hand. I tried my best, but handling such a fine brush through a microscope is definitely not one of my talents. Again, I realized how much work and artistry goes into these watches. After looking more at the aesthetics, we got to the more technical stuff; first up was the movement department.

From a design to a watch

On the table in front of us were all the pieces of the puzzle that make up the LFT023 movement inside the new Tambour. The “LFT” stands for La Fabrique du Temps, and the “023” is for the year it came to life. It’s a beautifully finished micro-rotor movement that took a lot of work to make as thin as it is. It’s funny because the micro-rotor is actually the thickest part. If it weren’t, it wouldn’t have enough weight to spin around. But when you look at the high-horology pieces that Louis Vuitton makes, the new Tambour almost looks like a jog in the park.

The movement developers also showed us computer models and three-dimensional prints of the brand’s Automata watches. Those are watches like the Carpe Diem and the Fiery Heart. These pieces incorporate animations on their dials, which I’m sure sound great on paper, I’m sure, but are an absolute nightmare to actualize. In the end, though, when you see them in person, you can see the complete amalgamation of all those different crafts in just one watch. And that’s precisely the magic that Louis Vuitton would like to keep alive with its La Fabrique du Temps and the timepieces which it produces.

Case and bracelet construction

Next, we got a little insight into how the case and the bracelet for the new Tambour were developed. As the designers were aiming for a very slim case, the challenge was to make it reasonably water resistant. And as there’s a sapphire crystal both on the front and the back of the watch, that leaves very little space to put any gaskets. The other challenge was the bracelet. They told us it proved extremely hard to get precisely the right shape and feel for the links. This showed me just how many options exist and how designers must find the right balance between cost and aesthetics.

A room full of watchmakers

The final room we visited for the tour was full of watchmakers. In one area, there were six watchmakers fully responsible for assembling the new Tambour. The other watchmakers were working on the more complex higher horology pieces, like tourbillons, Automatas, and the Spin Time. I’ve been in departments like these now a few times at different watch brands, and it always feels special. It’s the department where they put life into the watches. It almost feels like magic.

Time to wrap up the tour

And how nice is it to look up from your workbench occasionally and see the Swiss Alps through your window? Ultimately, La Fabrique du Temps looks like a great workplace where various art forms and craft skills come together. It’s nice to have witnessed where the new Tambour comes from. But I’m also looking forward to what else is coming. Sure, the all-steel Tambour is nice, but now that I’ve seen what the manufacture is capable of, I’m hoping for even more exciting things from LFT.

Let us know in the comments below whether you’d like to work at a place like La Fabrique du Temps. Which of the disciplines would you like to master?