Celebrating 55 Years Of Titanium Watches With Citizen

Citizen recently organized a traveling exhibition showcasing its 55-year history with titanium. I was invited to the Paris edition, so I made my way to the French capital with my camera and notepad.

In case you were unaware, Citizen was the first brand to make a wristwatch out of this lightweight metal. While titanium may be common today, it was far from an obvious choice a little over half a century ago. The material wasn’t quick to give up its secrets, so it took a lot of technical pioneering. This unique exhibition told the story of how Citizen tamed titanium and made it a key part of its offerings.

The need for a titanium wristwatch

Citizen set out on a quest for alternative materials for watch cases in the 1960s. Remember, even stainless steel wasn’t universally adopted at the time, beyond the higher end of the spectrum. Especially in the more affordable segments, many watches still had chrome-plated brass cases.

Citizen decided to seek out a better alternative. The house quickly settled on titanium, primarily for its lightness and hypoallergenic properties. While talking to the engineers present at the exhibition, I learned that Citizen also strived for greater ergonomics. You can see this goal in many of the early titanium models. They pair the lighter metal with mostly rounded shapes for maximum comfort on the wrist.

Technical difficulties

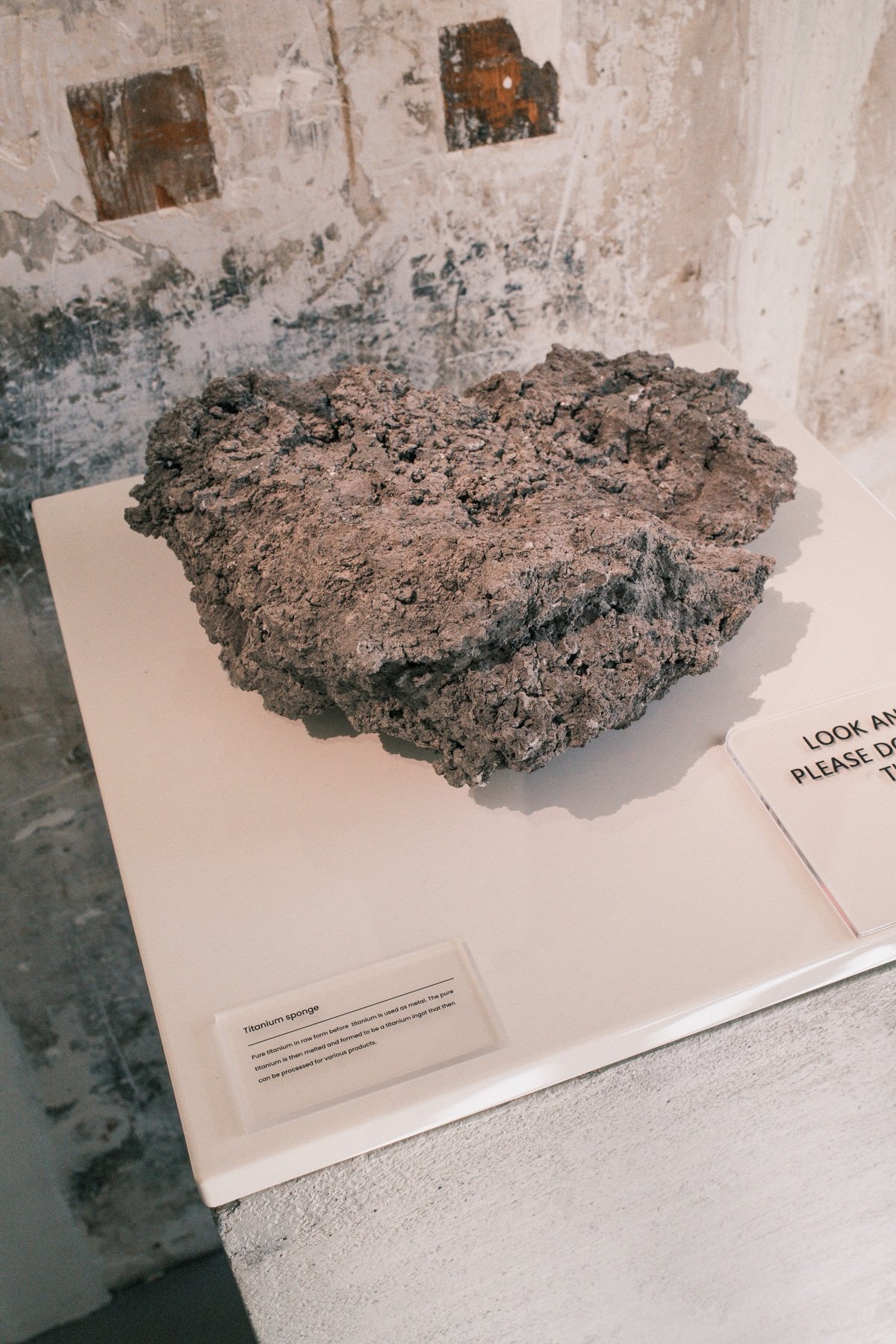

Titanium was far from the obvious choice in the 1960s. The metal is notoriously difficult to work with. Citizen’s engineers nicknamed titanium “triple trouble” since it couldn’t be pressed, machined, or polished.

Eventually, Citizen landed on a method in which a titanium rod is first heated and then pressed. The resulting case looks a bit like a waffle that spilled beyond the edges of the iron. The edges then get cleaned up before brushing and finally polishing the case. It did not become entirely clear to me what allowed Citizen to finish the metal that couldn’t be polished before, but clearly, the brand sorted it out.

One practical issue with titanium is how it shows signs of wear. Although titanium is harder than 316L steel, it immediately forms an oxidation layer upon coming into contact with air. That layer is darker than the titanium underneath and scratches very easily. Citizen invested heavily in a process they called Duratect. This adds an ultra-hard, scratch-resistant layer. The resulting material is called Citizen Super Titanium. The brand then continued its development with different ultra-hard color coatings.

The titanium exhibition

On to the exhibition. Naturally, tons of titanium Citizen watches were on display, but visitors could also touch them. Kudos to Citizen for offering us the opportunity to handle the watches rather than keeping everything behind glass. For me, the highlight of the collection was the Citizen X-8. This was the first-ever titanium watch, dating back to 1970. Unfortunately, this feat doesn’t quite get the same respect and applause as other horological innovations.

A secondary room featured an installation comprised of thousands of titanium swatches in the different Citizen colors. The swatches formed organically shaped clouds, with watches representing each finish suspended above. A video played in the background, bathing the entire installation in a mesmerizing, flickering light.

A space connection

Citizen took inspiration from the advancements in space exploration in the 1960s and the prominence of titanium within it. The brand continues that connection by sponsoring the Japanese iSpace Inc. and its Hakuto-R program.

In fact, Hakuto-R builds its lunar landers using Citizen’s Super Titanium. The feet of the landing gear are made of this hardened alloy. The program aims to land on the Moon but has failed so far. Its first two missions crashed on the lunar surface. A third mission is planned, which will hopefully result in the Citizen Super Titanium feet landing softly and safely on the Moon.

Closing thoughts on the Citizen Titanium exhibition

Citizen is smart to bring its prominence in titanium watchmaking back to the attention of the watch media. After all, introducing the material to the watch world had a massive impact. Today, titanium is one of the most popular alternatives to steel, partially due to Citizen’s enduring influence. As watch enthusiasts, we tend to obsess over the tiniest of horological innovations, except if they happen outside of the movement. Still, I reckon the introduction of titanium should be part of the horological canon.

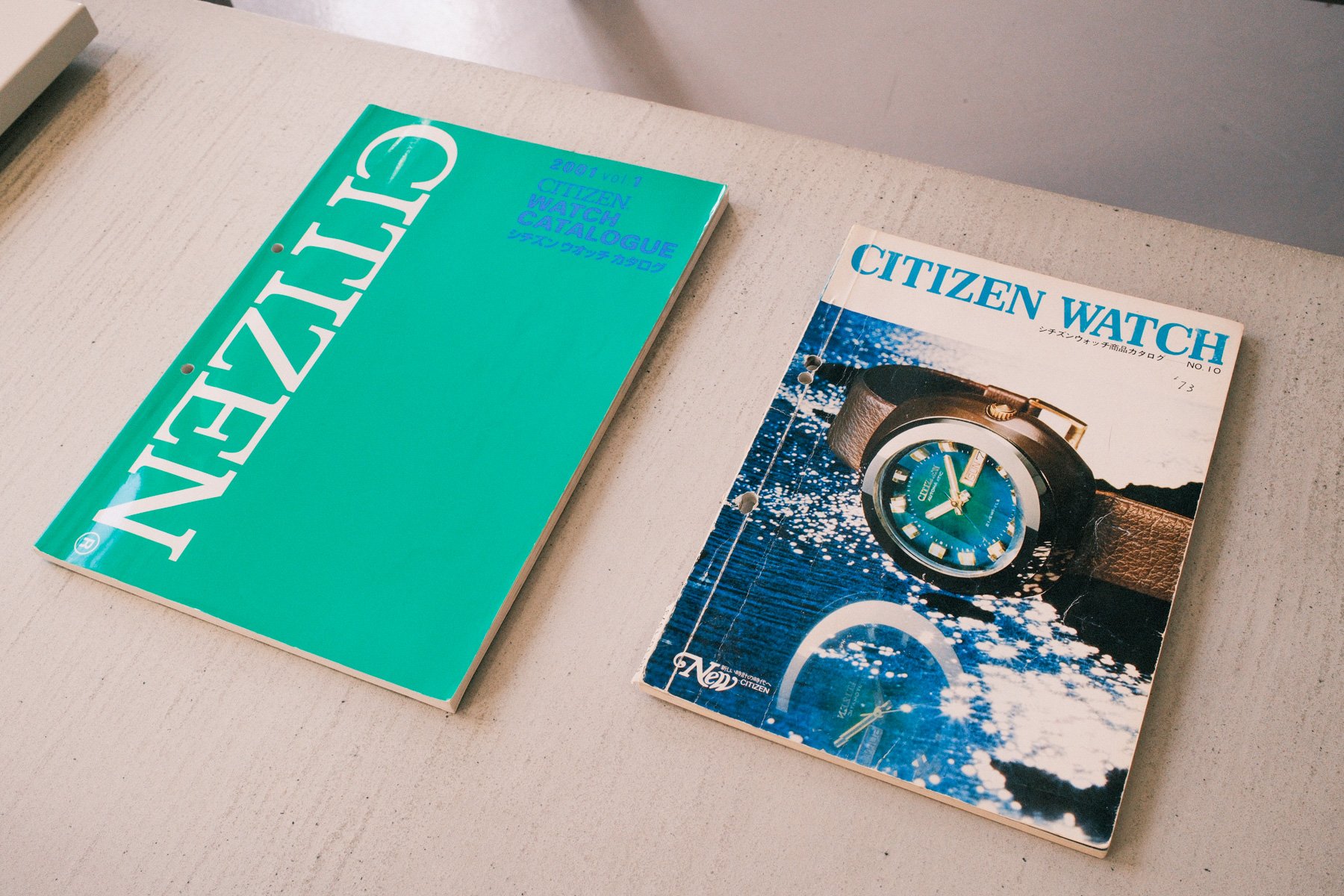

For me, it was great to meet some of the engineers and commercial staff behind the brand. Speaking to them, I saw the devotion and drive needed to keep a company like Citizen on top of its affairs for so long. Similarly, seeing vintage catalogs, posters, and other materials provided a rich context that is hard to grasp otherwise.

When I asked about the future of titanium in watchmaking, I received a slightly secretive response. One thing was clear, though: titanium will remain a strong focal point for the brand. I would like to thank the folks at Citizen for their hospitality, and I look forward to many more lightweight creations!

What do you think of Citizen’s titanium watches? Let us know in the comments section below!