Factory Visit — Czech Prim Manufacture

There isn’t a single household without at least one Prim watch, or so says an old saying from former Czechoslovakia.

We all live in different corners of the world. We all speak different languages. And we certainly all have our local heroes and legends. I am not just speaking about people. Often, there are local brands that no one 200 meters beyond the border of the country care about. But within those borders, such brands come to mind faster than any world giant.

If it weren’t for communisim, Prim probably never would have been born…

There are 10.5 million people living in the Czech Republic and 5.5 million people living in Slovakia. The two countries used to be united as Czechoslovakia (until 1960) or as the Czechoslovak Socialist Republic (CSSR) until the early ‘90s when they separated and established themselves as independent countries. Czechoslovakia was a satellite state of the Soviet Union and ruled by communists. If it weren’t for communism, Prim probably never would have been born and reached such a cult local status. I bet you that locally, more people know Prim than a brand as globally recognized as, for example, Seiko.

Let’s build a watch factory

Prim was founded the same year as my father was born, in 1949 — one year after French YEMA (another one of my favorite brands) was founded. At that time, only seven countries in the world could produce watches — Switzerland, Germany, the US, France, Great Britain, the Soviet Union, and Japan. Deciding to build a watch factory in Czechoslovakia in the middle of nowhere and without any watchmaking heritage was pretty crazy. A mission impossible. Or so it might have seemed. But not for very cost-aware socialists.

Five years of prototyping

The seven-hundred-page thick encyclopedia (no kidding) on Prim watches written by Anton Hovorka says that “the average lifespan of a watch was around 15 years back in the fifties.” Czechoslovakia needed 250,000 new watches a year and being able to produce them within its borders would bring a lot of savings for the state coffers. A little country in the heart of Europe with zero experience in watchmaking only took five years to build its first watch. Serial production started three years later in 1957. The moment there was enough stock volume, sales officially started on April 1st, 1958.

It took engineers years…

Inspiration for the first in-house caliber 50 was the French movement Lip R25-3. The technical team visited GUB Glashütte in Germany and a few other manufacturers in the Soviet Union. The first prototypes were created on universal machines. These were far from the special machinery required for fine watchmaking. It took engineers years to develop special materials and to secure local production of movement parts in local factories.

Impressive archive

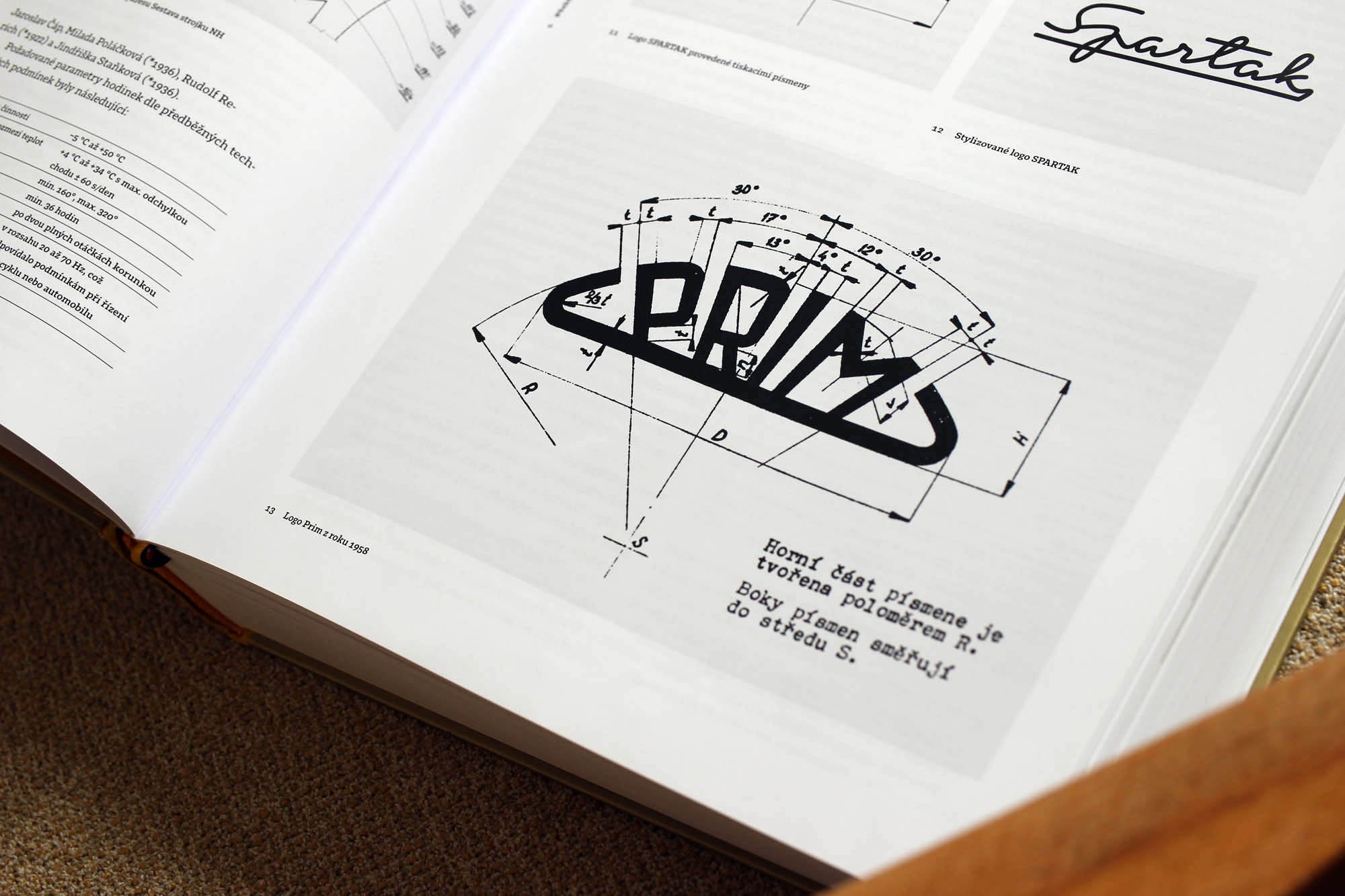

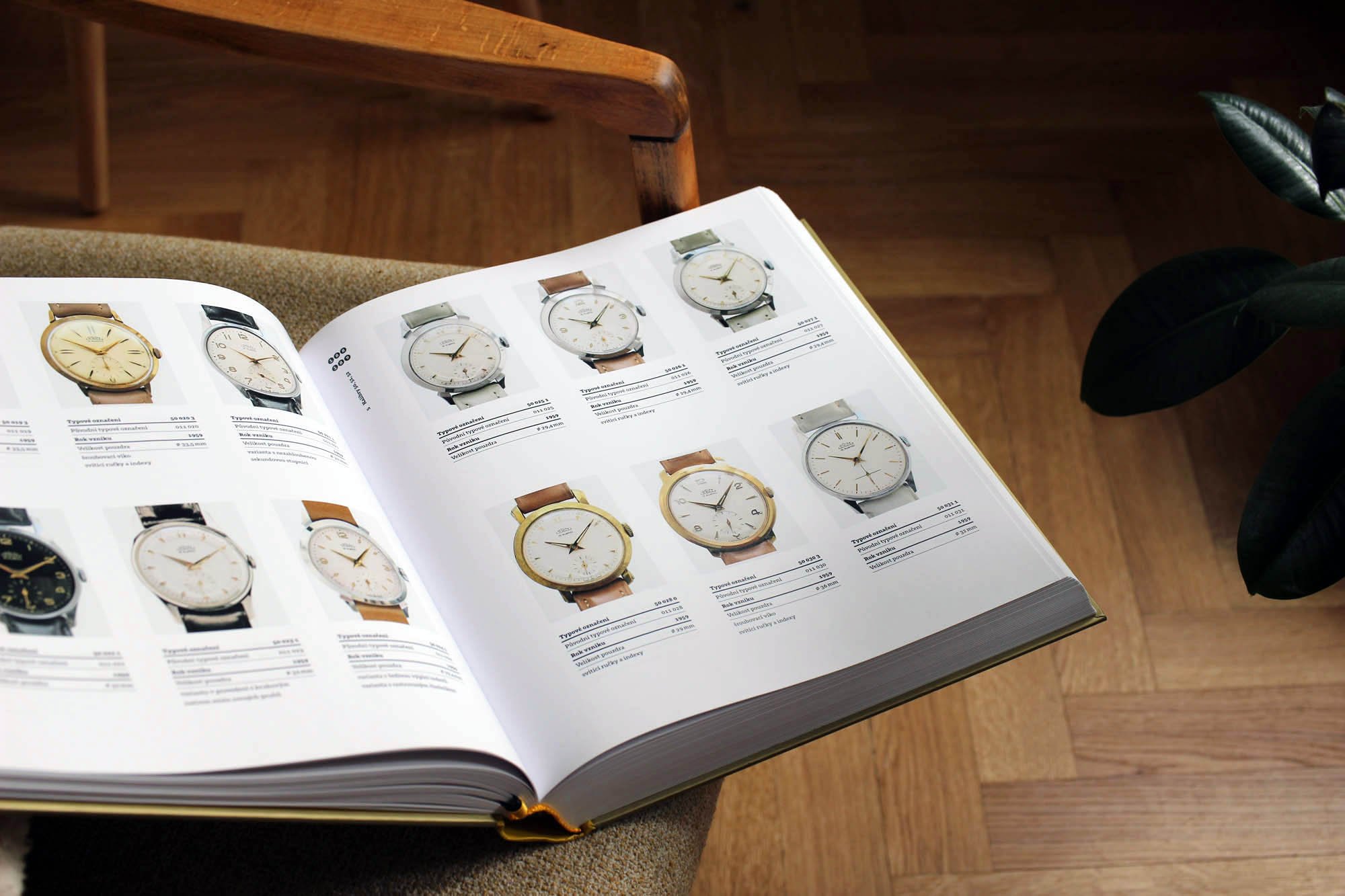

The first Prim watch ever created was called Prim Spartak. Within a few years, production grew to more than 100,000 watches per year. In the early ‘70s, Prim produced nearly half a million watches and clocks in-house. Surprisingly exhaustive archives list around 800 different manual watch designs between 1958 and 1994.

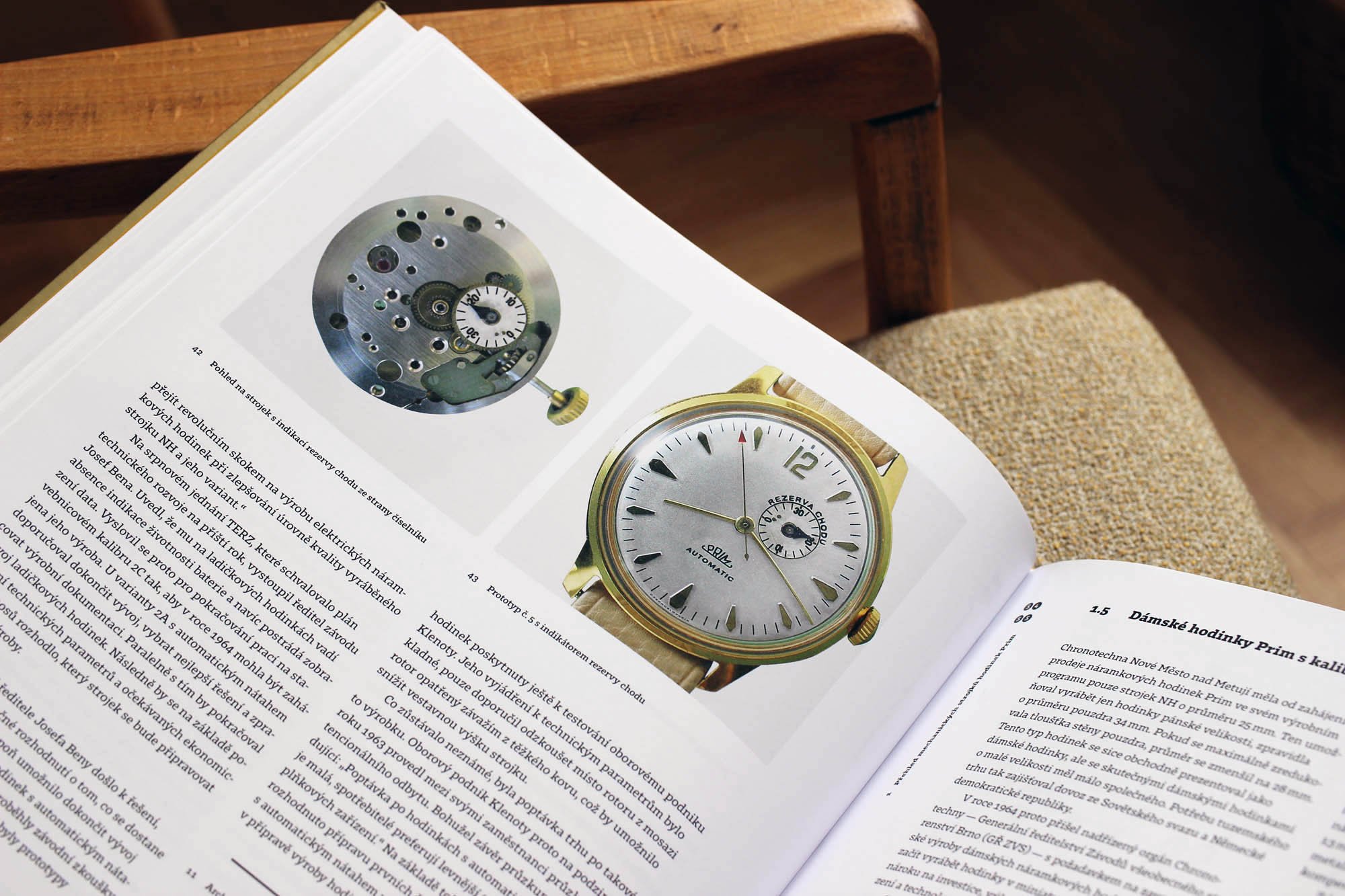

The book on the history of Prim also documents watch prototypes. These include a power reserve model or the brand’s very own quartz movement. In 1989, the year of the Velvet Revolution in Czechoslovakia and the fall of the Communist one-party rule, Prim was still producing 300,000 watches annually. A few years later, in 1994, just a year after forming two independent republics, production dropped to 20,000 watches a year. By that point, Prim’s fate was all but sealed.

Back to form

You can only imagine what opening the borders and the market meant for a local producer. Wearing Prim was not cool anymore. Wild privatization of the two companies behind Prim’s production also brought long-standing lawsuits regarding the Prim trademark. The production site, however, has never been moved. It is still based in Nove Město nad Metují in the Czech Republic. Twenty years after the Velvet revolution, people remembered the local watch brand and became excited by mechanical watches again. Production was modernized thanks to considerable investment from a private investor. Today, Prim produces primarily manual or automatic mechanical watches. Astoundingly, the brand now offers six in-house movements.

Smaller production volumes

Today Prim focuses on fine pieces in smaller production volumes. “We make around 650 mechanical watches a year,” says Prim PR manager, Adéla Dittmannová. “We are one of the few manufactures in the world that can produce almost all the parts necessary for a mechanical piece — watch case included,” says Adéla proudly.

Swiss sub-contractors supply less than 10 parts from the overall 130 parts in Prim movements.

After a deeper study, I learned that Swiss sub-contractors supply less than 10 parts from the overall 130 parts in their movements. If possible, Prim always tries to find a local producer first. For premium leather straps Prim didn’t reach out to Italy, but rather a local leatherworks manufacturer, Tlusty & Co. The Czech premium leather they fit on their best watches is of superb quality.

Local luxury

Like many brands, Prim also re-created a few of its iconic models. The Prim Spartak, Orlik, and Diplomat are all true to their vintage forebears. Prices reaching 2,500 or 3,500 Euros suggest that Prim has a pretty creditworthy clientele. Even more so if you realize that its strictly limited editions — such as the recently featured Prim Aviatik — go for over €5,000 and don’t struggle to sell out. Prim definitely needs to create a new e-shop for foreign buyers. That would be an essential step for the brand to start reaching a global audience. That is something I believe Prim could achieve. Even in this climate…

Truly independent

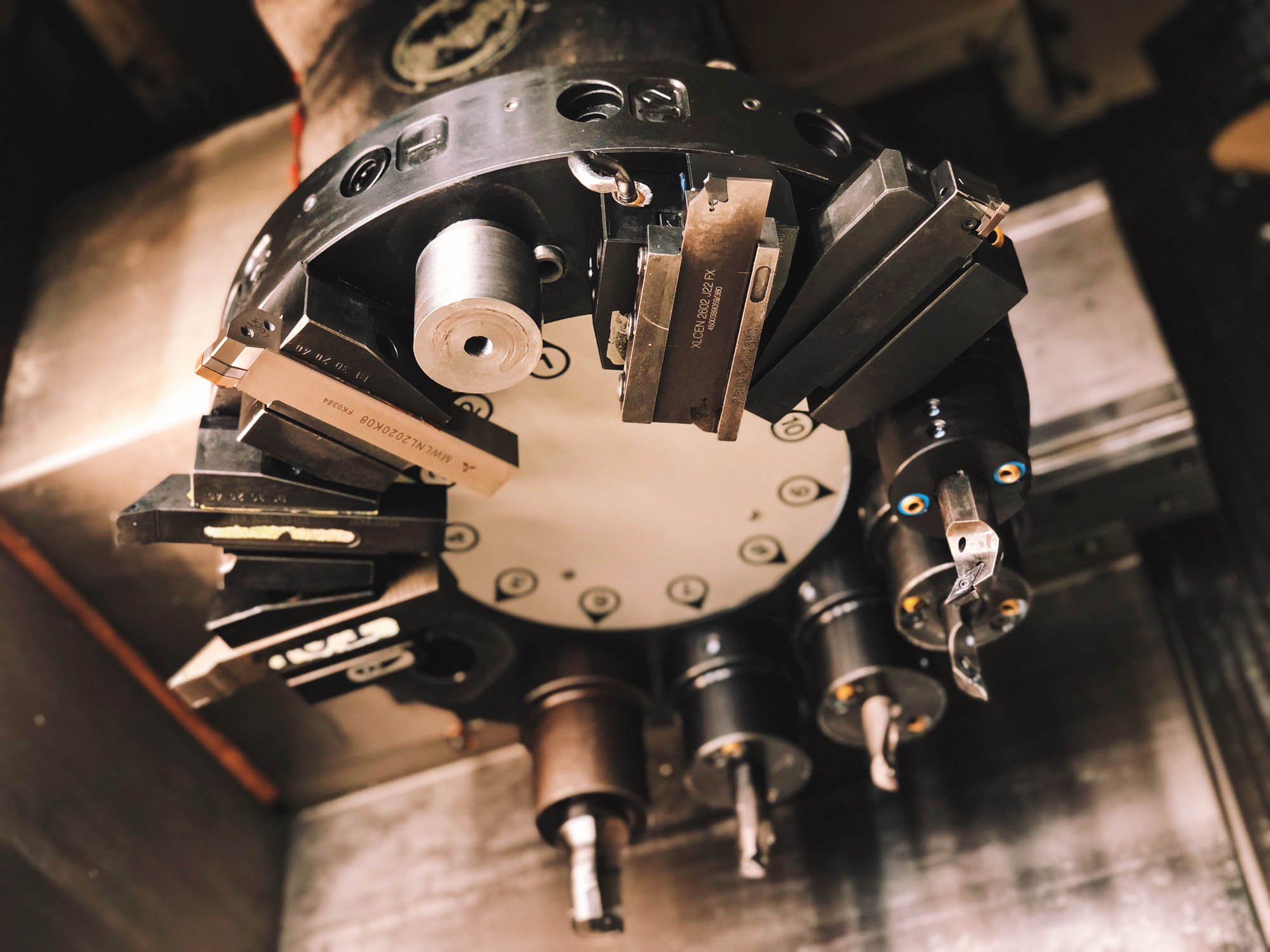

What I like about Prim is its accessibility. For locals, at least, from what I know. You can arrange a visit to the headquarters and production site as well. Last year, I visited with my wife. Prim took us on a three-hour private tour through the factory. We were shown all stages of the production process. The transparency was really refreshing. We could ask whatever we wanted to know and the sales director Ales Vernar patiently responded. We were surprised to see a bunch of 50- or 60-year-old tools alongside state-of-the-art machinery. “The level of quality that some of these tools provide is sometimes irreplaceable,” says Aleš.

By hand

All cases for Prim watches are manufactured within the factory by chip machining technology. This method allows for huge flexibility. Prim processes a variety of materials from stainless steel, to precious metals like damascene steel or titanium.

To see the special layered pad printing live was very satisfying.

All final finishing is done by hand. Visually, the most interesting part of the tour was the dial production. To see the special layered pad printing live was very satisfying. As the age-old saying that one look is worth much more than a thousand words goes, I invite you to flip through the images we took throughout our Prim Manufacture tour.

For more information about Prim Manufacture you can visit the brand’s website. You can also look forward to seeing a hands-on review of their last release, the Prim Masaryk, on Fratello. A limited-edition of 100 pieces of an unusual “one-hander“ paying tribute to the first Czechoslovak president Tomáš Garrigue Masaryk.

- Lathe STAR SR-10 for movement parts production create the tiniest elements in size of 0.8mm.

- Showcase, literally. Demonstration of different cases, case backs or tailor made customisations.

- Special lathe with a revolver head has attached multiple tools for various use.

- Production process step by step.

- Pad printers for dials

- Special devise KIRA for case-back engraving.

- Some of legendary Prim designs.

- Original PRIM logotype.

- Prototype of a watch with a power reserve.

- Prim also renovates old watches .