Inside The Tudor Manufacture — A Visit To The Brand’s METAS Laboratory

It’s not every day that you get an invite from the folks at Tudor to come to see their manufacture and METAS laboratory in Geneva. So we gladly accepted their invitation, and Ignacio and I found ourselves in front of the impressive green Rolex building on a Thursday morning at 8:00 a.m.

Tudor Black Bay Ceramic Master Chronometer

Since the introduction of the Black Bay Ceramic ref. M79210CNU-0001, Tudor has a watch in the catalog that can call itself a Master Chronometer. This relatively new standard debuted in 2014 at the hands of Omega and the Federal Institute of Metrology (METAS) in Switzerland. This independent organization is responsible for the testing procedures and the actual certification of the watches. I explained all the details, in this article here.

Tudor Movements

Just like Omega, there’s a separate lab inside Tudor manufacture where METAS performs the testing on the watches. After Ignacio and I changed into our Tudor-branded white watchmaker coats and plastic overshoes, we were allowed to enter the floor where Tudor watches are assembled. The production of the parts (cases, bracelets, movements) takes place elsewhere at suppliers’ facilities. Since 2016, the movements themselves have been produced by Kenissi, which is owned by Tudor and Chanel. Today, Kenissi delivers movements to both of these brands, as well as Norqain and Breitling.

METAS Labs inside Tudor HQ

Upon entering the Tudor department inside the Rolex headquarters, you see a path that leads to the end of the room. On the left and right are a lot of workbenches with technicians assembling watches. There, you’ll find them casing the movements and applying hands to the dials using specially developed equipment. Interestingly, Tudor informed us that the brand doesn’t share any production with Rolex.

All components for Tudor watches come from several suppliers, but rather surprisingly, not from Rolex. I expected at least some sharing of production capacity, but this is not actually the case. These days, Tudor’s production is completely separate from the Crown. What they do share (for now) are the building and the support departments — think HR, IT, and so on.

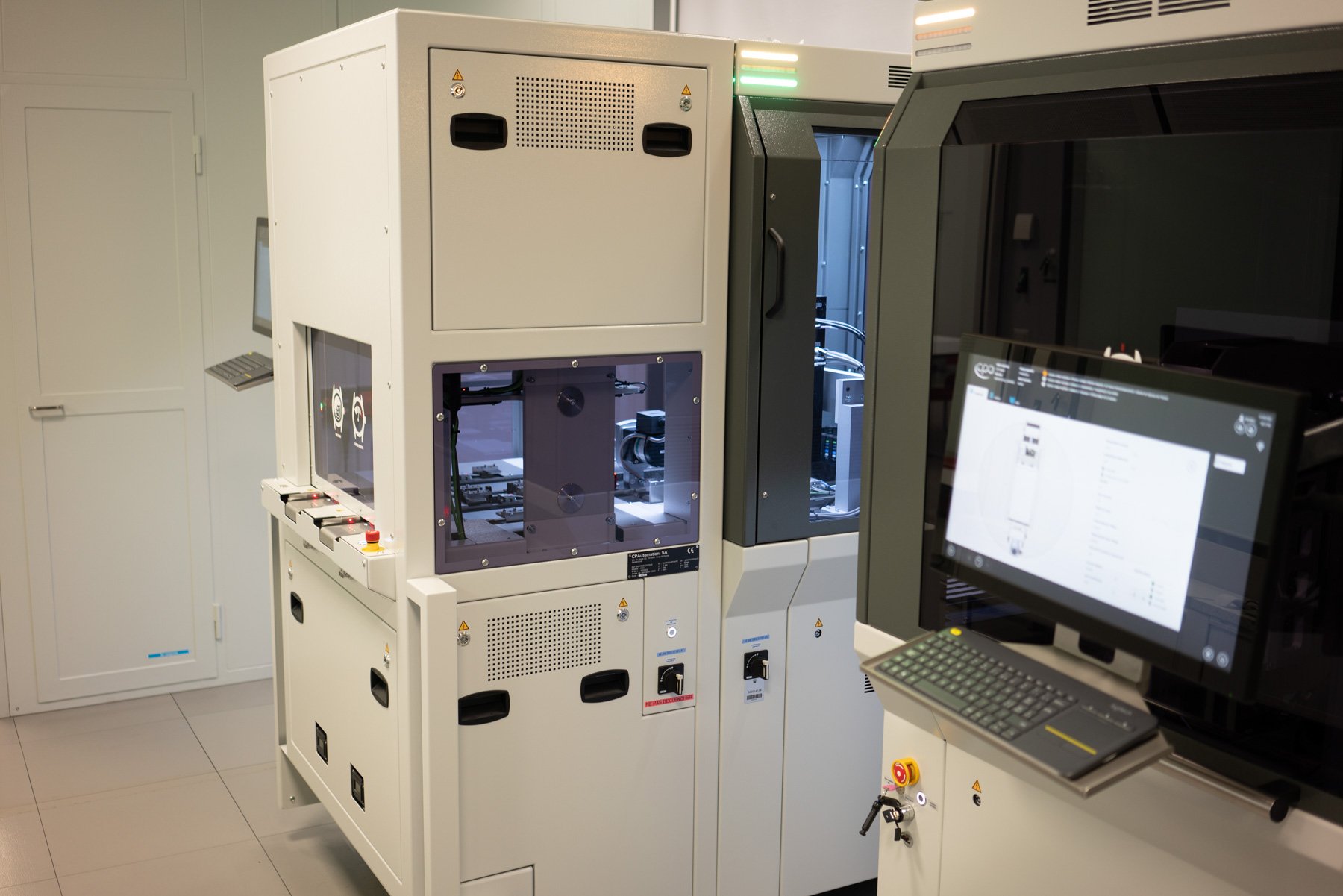

Testing equipment

In the center of the assembly room, there’s a glass door that reads “Tudor Master Chronometer”. Here is where Tudor watches are tested against the Master Chronometer framework. Before that takes place, all movements need to be certified by the COSC organization. As this is a different process, it takes place externally, unlike the Master Chronometer certification. After the movements pass the COSC tests, Tudor watchmakers case them up before Master Chronometer testing.

METAS Standards

All Tudor Black Bay Ceramic Master Chronometer watches undergo the same tests for accuracy, anti-magnetism (up to 15,000 gauss), accuracy with 30% of their power reserve, and water resistance. Starting with the last one, all watches are tested with special equipment to exceed a depth of 200 meters. The accuracy of a Master-Chronometer-certified watch needs to be in the range of 0 to +5 seconds per day on average.

The intimidating magnet inside the METAS Laboratory

Inside the METAS laboratory, the staff performs the tests on every single watch that requires Master Chronometer certification. Most impressive is the huge magnet inside this room, which exposes the watches to forces greater than 15,000 gauss. A tray filled with Tudor watches goes inside for half a minute or so, and afterward, the staff checks the watches for accuracy again. If all goes well, the powerful magnet should have no effect on their precision. Interestingly enough, there’s this weird vibe around this magnet. There’s a sticker indicating you shouldn’t come near it if you have a pacemaker. Apparently, though, it’s fine to come really close without one. The thing just looks kind of intimidating, to be honest.

Pressure testing

In a separate room in the METAS laboratory, there’s the equipment for the water-resistance testing. Here, the watches are tested with a +25% margin. After the Black Bay Ceramic passes all the tests, the in-house METAS laboratory staff will certify it as a Master Chronometer. Only watches that have a COSC-certified movement and have passed the stringent METAS testing are allowed to have “Master Chronometer” printed on the dial.

Some afterthoughts

To me, it is interesting to see that Tudor has this METAS “test street” set up in the middle of its assembly department for just this one reference. I can’t imagine that Tudor planned to do this for just one watch. The reality is, however, that no other watches since the 2021 Black Bay Ceramic have carried this certification. It could be part of a strategy in which Rolex is using Tudor to compete with Omega, showing the brand is also capable of delivering Master Chronometers. But who knows? What I do know, however, is that overall, the METAS standards are stricter than those of Rolex watches. Thus, it would have made more sense for Rolex to adopt these standards as well. Then again, that would also mean that Rolex picked up the gloves against Omega and has become a follower instead of a leader.

We’d like to thank the folks at Tudor for their invitation and for giving us a peek inside their manufacture and METAS laboratory.

What are your thoughts on these strict testing procedures and this type of certification? Is a COSC chronometer certificate still good enough, or is it a good thing brands keep pushing for higher standards?

Header image courtesy of Rolex.