Introducing: The Oak & Oscar Humboldt ExP-02

It’s been nearly a year since we’ve heard from Chase Fancher and the team at Oak & Oscar. Here we are, though, in late January with an exciting, albeit highly limited, new release. Hopefully, the Humboldt ExP-02 foreshadows an increased level of in-house production capability. For now, let’s take a look at the watch!

I always like to mention that we’ve followed the journey of Oak & Oscar and owner/founder Chase Fancher from the brand’s beginning in 2015. Over time, different complications have joined the lineup with great success. A good example of this is last year’s Atwood, which features a hand-wound chronograph movement. Today’s Humboldt ExP-02 keeps things relatively simple within the engine bay, but it impresses with some key components made at the company’s headquarters in Chicago.

The Oak & Oscar Humboldt ExP-02

At first glance, I thought I was looking at a new version of the venerable Olmsted 38mm, but I was incorrect. No, this model’s platform is the Humboldt, a watch that was only available in GMT versions until now. This also means that it has a 39.5mm by 46.8mm stainless steel case, which is slightly larger than the Olmsted. Still, the dimensions put it firmly in medium-sized territory. It also has a 12.4mm profile, including the double-domed sapphire crystal on the front and a screw-in stainless steel and sapphire case back. A screw-down crown also helps keep everything protected to a depth of 200 meters underwater. For reference, the watch comes exclusively with a three-row steel bracelet and an easy-adjust clasp that could best most macro-brands.

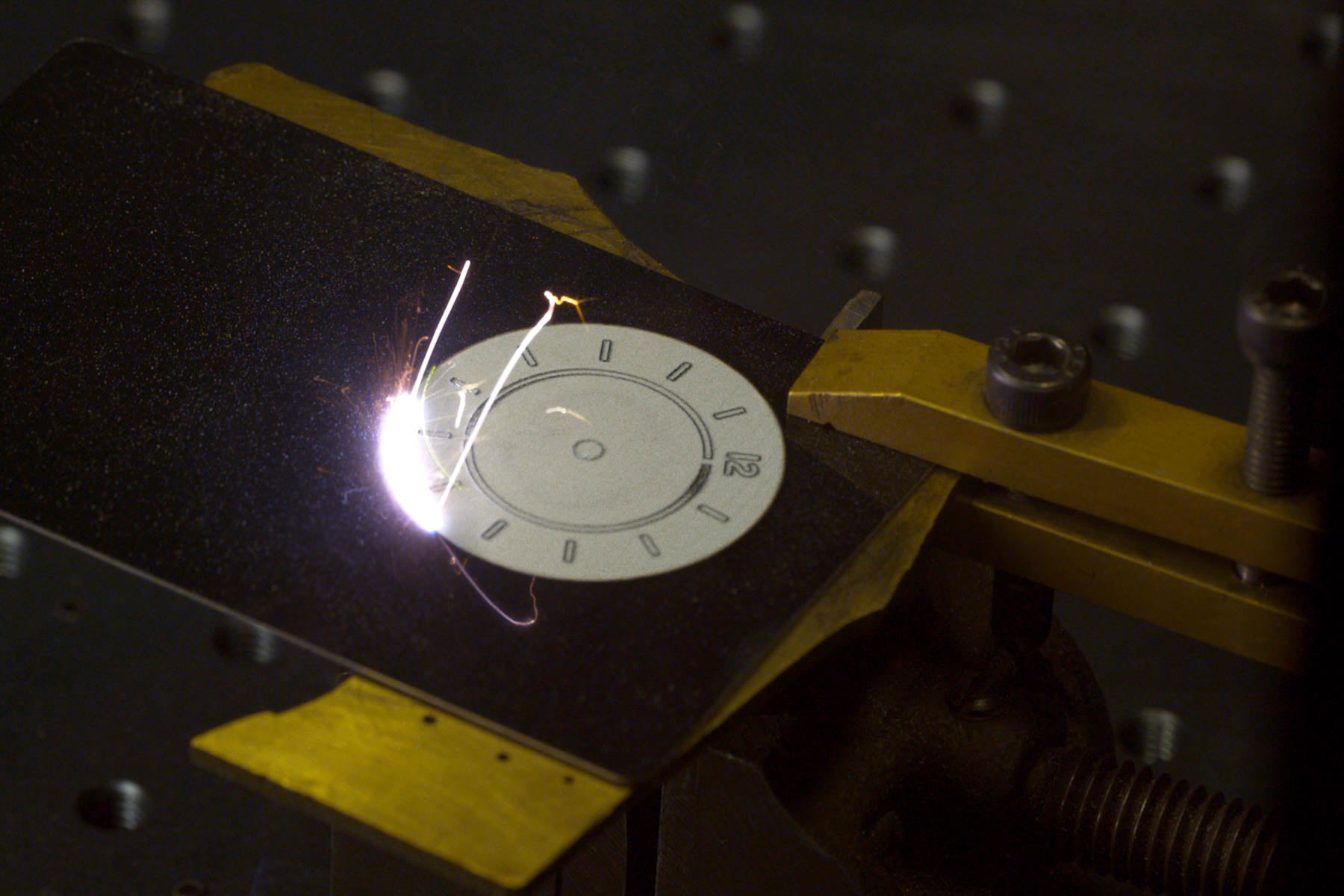

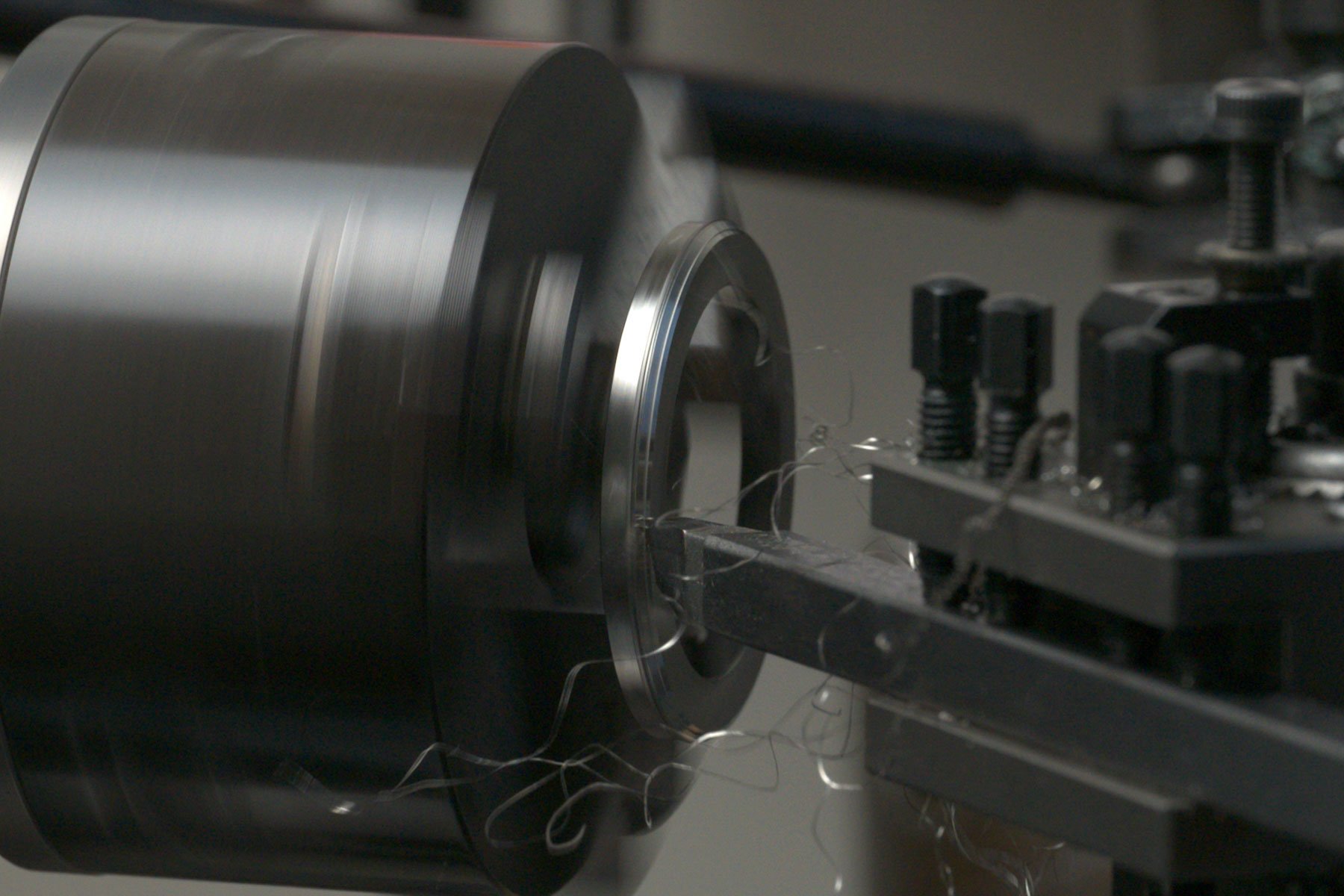

Firing up the lathes and lasers

So, what’s so special about the Humboldt ExP-02? For starters, Oak & Oscar produces two key components internally using a Schaublin 70 lathe. The chapter ring, which sits between the dial and crystal, is machined from aluminum tubing. Then, the dial, with its gray appearance, is cut out from an aluminum sheet using a 100-watt MOPA fiber laser. To create the sandwich effect, an Oak & Oscar hallmark, the same laser removes material for the indexes, central pinion, and circular motif. The chapter ring and dial are bonded together and blasted with media to create a matte finish. Once again, the laser handles all writing on the dial. The bottom dial layer, which is attached to the movement, is black anodized aluminum.

Also, the team at Oak & Oscar uses the lathe to produce the external stainless steel bezels. With this hand-machining operation, they can achieve impressive 0.01mm tolerances. Finally, the hour and minute hands with Super-LumiNova BGW9 and an orange sweeping seconds hand provide great legibility.

Powered by the Sellita SW300 automatic

We don’t yet have a photograph of the case back, but we expect a nicely finished movement with a bespoke oscillating rotor. The watches house the Sellita SW300, a workhorse caliber with 56 hours of power reserve and a frequency of 28,800 vibrations per hour. All the regular features, such as hacking and manual winding, are along for the ride.

Availability and pricing for the Humboldt ExP-02

All told, the Humboldt ExP-02 is a sharp-looking watch with a dial design that’s hard to dislike. Plus, as a fan of smooth-bezel tool watches, I like this take on the Humboldt. The fact that Oak & Oscar produces the dial and bezel within its four walls only makes the piece more endearing. The challenge, unfortunately, is that, currently, this US$2,550 watch is severely limited. Think of it like a skunkworks project, and the “ExP” name begins to make more sense. Oak & Oscar will produce just 20 of these watches, with the first 10 reserved for existing owners and the second 10 available to the general market. The caveat, though, which is a positive, is that Oak & Oscar will open a lottery from January 27th through February 3rd. Via a link on the brand’s website, potential buyers can register for a chance to win a buying opportunity.

What do you think of the Humboldt ExP-02 and Oak & Oscar’s trajectory? Share your opinions in the comments below.