Building A Watch Brand Episode 9: 3D Modeling, Tech Development, And Opening Up On The Mentally Challenging Side

A while ago, we completed the concept design/target aesthetic of my upcoming VPC Type 37HW. Now we are in the stage of 3D modeling and technical development. This slow, arduous process takes extensive iterating and is probably the least glamorous part of creating a watch. Therefore, you typically don’t see much of it, so I’m happy to lift the curtain and reveal what happens between design and production.

On a more personal note, I am also sharing some of the more mentally challenging aspects I have run into. Building a watch brand is a massive source of joy for me, but it comes with some downsides that I think may be worth sharing too. I promised to share the entire journey, so it feels wrong to skip that side of it. We have a lot to cover this time, so let’s dive in!

3D modeling

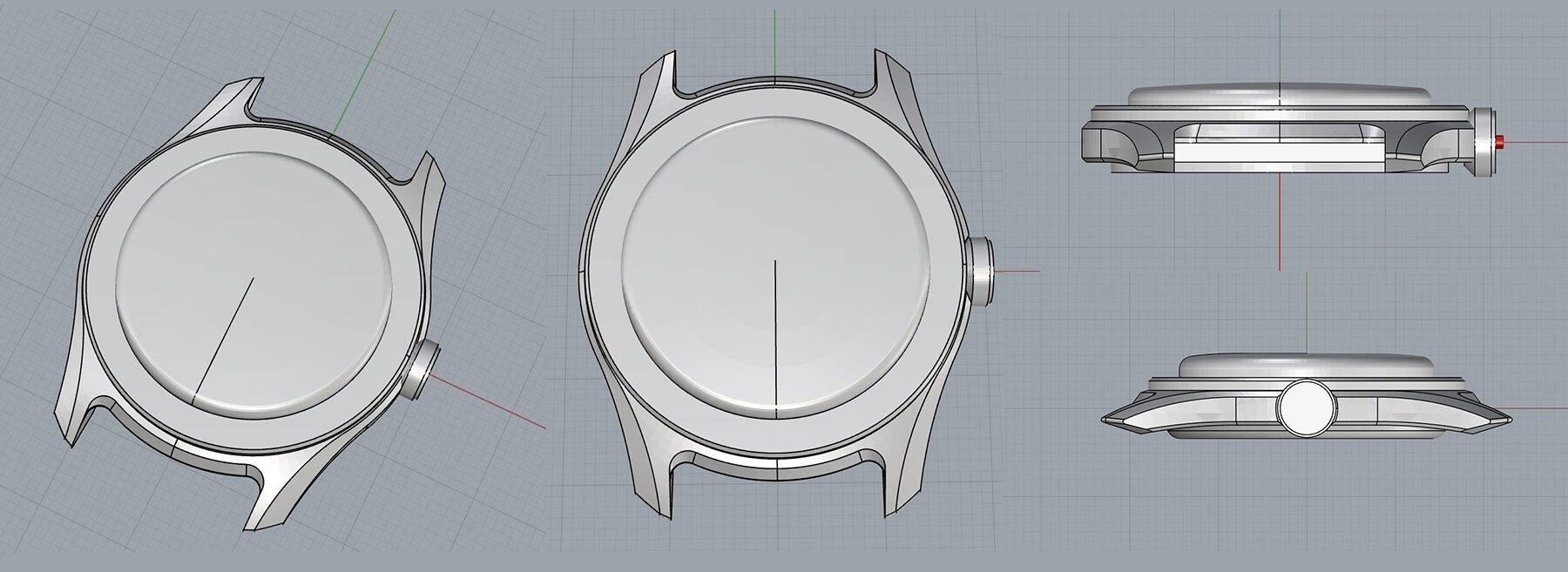

Everything I have shown you in previous articles has been two-dimensional. Even the semi-realistic images were merely flat drawings. Max Resnick has done front and side profiles, but as you can imagine, there is a lot more to a fully three-dimensional watch, so that is where we went next.

3D modeling is done in CAD (computer-aided design) software — Rhino 3D in this case. Once Max and I were happy with the concept design, he started building it up in Rhino. This is a crucial step for several reasons. First, it lays bare a ton of nuance that doesn’t come across from your plain front and side designs. Second, the result will be the actual files that manufacturers will use to produce the watch, so they have to be spot on.

This is also where creative ideas become serious. That ledge of ours, for instance, now gets fully shaped, accounting for an end link and manufacturability. The 3D modeling phase is where you run into the challenges you have set yourself during the aesthetic design phase.

From 3D modeling to 3D printing

3D modeling also opens up the possibility of 3D printing prototypes. I cannot stress enough how huge this is. I have been wearing different iterations of the VPC Type 37HW case over the past weeks, and I have learned so much. We have caught improvement points that we would have never seen until much later and that we wouldn’t be able to iterate on nearly as much.

The first version (the black one in the pictures) confirmed that the 37.5mm diameter has precisely the desired effect. It bridges the gap between vintage and modern in terms of size. It really sits slap-bang in the middle between a Rolex Explorer 36 and 39 in perceived size. The thinness, currently at circa 9.3mm, is really neat too. The lugs, however, felt a bit short. They made the case a bit too bulbous and stubby, so it was back to 3D modeling for a v2.

The second iteration with longer lugs in a finer-resolution plastic 3D print. You can spot the issue with the lugs sticking out, which is currently being fixed.

The second iteration (gray in the pictures) is fitted with longer arching lugs. They add a ton of presence and flair. This case sits great on my 17cm wrist (pictured) but works equally well on some larger wrists we tested it on. The lugs angle downward quite aggressively, which makes for a lovely stance on the wrist. Unfortunately, when you mount a strap to the closest lug holes, the lugs stick out. So when you optimally use the ledge for a gapless fit, the lugs are too long. There is no such issue on the outer holes, but that isn’t good enough, of course. So Max is currently fixing that in 3D modeling for the next version. Naturally, we’ll keep iterating until we feel it is just right.

From 3D modeling to tech development

3D modeling also naturally leads to the first stages of technical development. For instance, we have now learned what thickness of sapphire and case back are required for specific water resistance ratings. Thus, we have decided to aim for a 100m rating for the Type 37HW. To achieve a 200m rating would require the case to be roughly 1.3mm thicker. We tested it in 3D modeling and lost that noticeably thin profile. So 100m water resistance and a sub-10mm height are the way to go in my book, especially considering that this is a do-it-all-style watch. We have some plans lined up for an automatic dive watch on the VPC platform in the future. We’ll reserve the slightly thicker and even more water-resistant construction for that one.

We have also found that our ledge design does not allow for a push-button quick-release end link. There simply isn’t enough height under the ledge to put it in there. So we will opt for a double bayonet-style quick-release mechanism that does fit. Now it is a matter of sourcing one that is thick and sturdy enough to meet my standards. As with anything, if I can’t do it properly, I don’t do it. Features like quick-release and micro-adjustment can never come at the expense of reliability and quality, so I will omit them if that becomes a consideration at any point.

This is the type of technical consideration we are making at the moment. This should result in the final designs sometime soon. The resulting design pack then gets handed from Max Resnick to the business that coordinates the manufacturing for me in Switzerland. And then we are truly entering the prototyping and production stages.

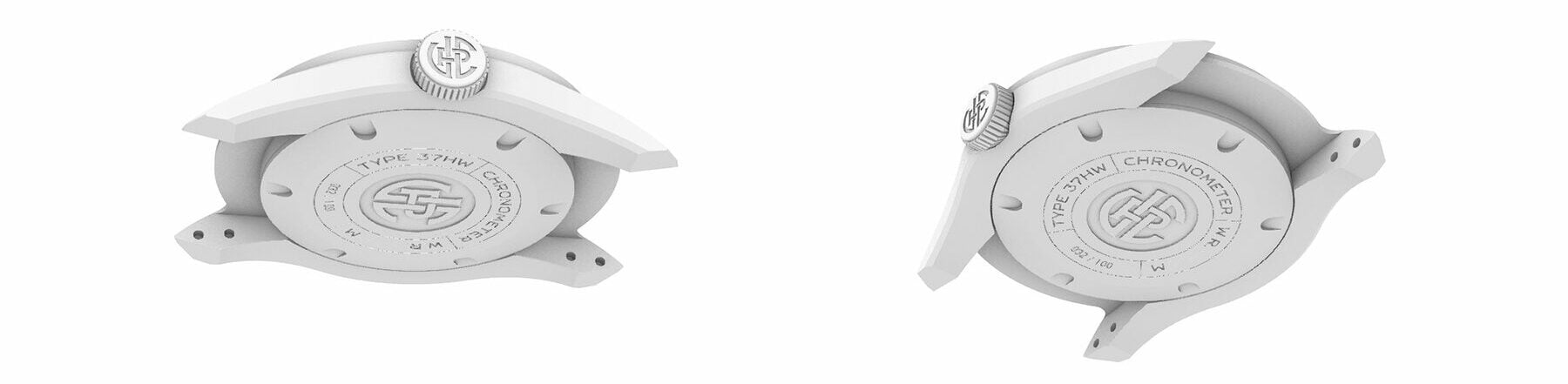

Case back design featuring the monogram and fully custom VPC typeface by Samuel Baker (serial numbers are a placeholder, not representative of actual available units)

Mentally challenging aspects of building a watch brand

I have great reservations about whether I should address the following. However, since it is a significant part of how I experience the project and I promised to share it all, I feel I should. Working on VPC is easily the most fulfilling, inspiring, and motivating thing I have ever done professionally. It is really turning out to feel like a calling. It is more and more like I absolutely have to do this.

Social media and Fratello give it a chance of succeeding. Both allow me to get the word out and connect with people who may want to own and wear a VPC watch in the future. I am, however, generally quite allergic to strong opinions. It makes me sad when people think to hold the truth. For that reason, I don’t watch talk shows, I don’t typically read or post comments online, and I never engage in forums. In fact, working at Fratello is the first time I have received anonymous reactions to my work daily. And, to be honest, it is not the most fun part of the job, especially now with VPC, a project that is so close to my heart. The constant stream of comments and DMs can get to me. If I actually received two cents every time someone offered their two cents, I’d have a thriving business already.

Yes, I do see the irony since our very job at Fratello is sometimes to comment and review. My experience here has certainly made me more measured with criticism. After all, people read my articles to get my perspective on something, but it has to be proportionate. Psychologically, however, there is a difference between getting a considered article written about your watch and anonymous commenters sharing their (typically unnuanced) opinions on social media, forums, and places like Fratello. People have no problem publicly discarding or even scorning something you pour your heart and soul into for months in a casual sentence or two.

Feedback and engagement

This isn’t about feedback. I actively seek constructive feedback from people whose opinions I value. I don’t need to constantly hear that I am doing great. It is the unsolicited criticism that I’ve found gets to me after a while. There is a difference between a lighthearted “I wonder what it would have looked like if X” and remarks like “You should have done Y” or “If only you had done Z.”

Those remarks are pointless, really, as I am not trying to please everyone. I couldn’t even do so if I wanted to since half the comments demand the polar opposite of what the other half wants. I am developing a very personal vision of the perfect watch, hoping it will resonate with a small group of like-minded people in the end. It is heartwarming to see those people making themselves known to me already too! So any individual’s disliking of it has zero relevance to me, but it does trigger a negative sentiment within an otherwise extremely enjoyable emergent VPC community.

On a good day, I am just happy my work triggers something in people. On bad days, I must admit, I do get quite discouraged by the umpteenth “I think you should have done X” remark. It affects my mood, I am not proud to say. I know there are people following the series who are considering starting watch brands of their own. I would 100% recommend it, but this is something to consider and prepare for.

Closing thoughts on 3D modeling, tech development, and the less enjoyable side

The 3D modeling stage is fascinating because it makes the watch come alive. Wearing the test cases is such a surreal experience. We have been working on this thing for months, and suddenly, there is an outline of it on my wrist. It is also great to see how close we will likely be able to remain to the original concept design. I have spoken to multiple nay-sayers in the business who claimed we wouldn’t be able to keep it this thin. Well, it seems like we are! It shows that it pays to be uncompromising and a tad stubborn.

I am afraid I will have to get used to the constant unsolicited feedback. The reality is that people see a social media post or an article as an invitation to share their opinions. One of the big advantages of microbrands is that you can engage with the founders and decision-makers, so I feel compelled to stay active and engage with those who are positive and constructive. In fact, I enjoy doing that. I am not expecting this to change, but I think it is only fair to admit that the negative ones take a toll on me.

As they say, if you can’t stand the heat, get out of the kitchen. It is just one of those things to which you cannot always predict how you will react. As it turns out, I have some self-improvement to do there if I am to last in this business. But when I turn away and just work on building an amazing watch, it all fades away. This is still easily the most exciting challenge I have ever taken on, so rest assured that it will not affect VPC. Next, I am working on finding the right part suppliers and manufacturers. More on that soon!

Can’t get enough?

- VPC website and newsletter opt-in

- VPC on Instagram

- Building A Watch Brand Episode 1 — Introduction

- Building A Watch Brand Episode 2 — Brand and name

- Building A Watch Brand Episode 3 — Finances, risk mitigation, and a designer

- Building A Watch Brand Episode 4 — Unveiling the watch concept

- Building A Watch Brand Episode 5 — The first design ideation sketches

- Building A Watch Brand Episode 6 — Caliber, pouch, case and bracelet updates, typography

- Building A Watch Brand Episode 7 — Dial design

- Building A Watch Brand Episode 8 — Geeking out on typography