Titoni Ltd. — How A Family-Owned Independent Made Its Own Watch Movement

Over the past decade, almost the entire Swiss watch industry has been under a cloud of uncertainty: ETA, the leading supplier of mechanical movements in Switzerland and part of the Swatch Group, has successively been reducing sales of movements to third parties since 2010. For several independent watch brands like Titoni, this has meant that only Sellita in La Chaux-de-Fonds remains as a reliable partner for affordable, good quality movements on the kind of scale ETA’s former cohorts require.

Although Grenchen-based Titoni has cultivated the art of traditional watchmaking, with a focus on mechanical watches, for decades, the company — like most watch brands in the mid-price segment – did not have its own culture of watch movements up until very recently. To minimize the risk of complete dependence on an alternative brand like Sellita, Titoni Ltd. decided to develop and produce its own movement.

What does it take?

“What does it take to make your own watch movement?” would appear to be a simple enough question, but, in fact, reveals the essential challenges of such an ambitious project. This is especially true for an independent watch company like Titoni that has not had any experience of producing its own watch movements in the past. Three things are needed before one can even think of engineering one’s own watch movement: money, know-how, and reliable partners.

The essential point was to find out what kind of motor the Titoni brand needed and wanted.

Thus, Titoni first had to define what kind of mechanical movement the company needed. In other words, the crucial question was: what is important and what isn’t? There are simply too many different possibilities in the world of mechanical movements.

The problem could be compared to that of car engines. A Ferrari engine is not the same as a Volvo engine — even though both are engines. A Ferrari motor is not necessarily better than one built by Volvo, but it serves a different purpose. The essential point was to find out what kind of motor the Titoni brand needed and wanted.

Costs, quality, and movement height

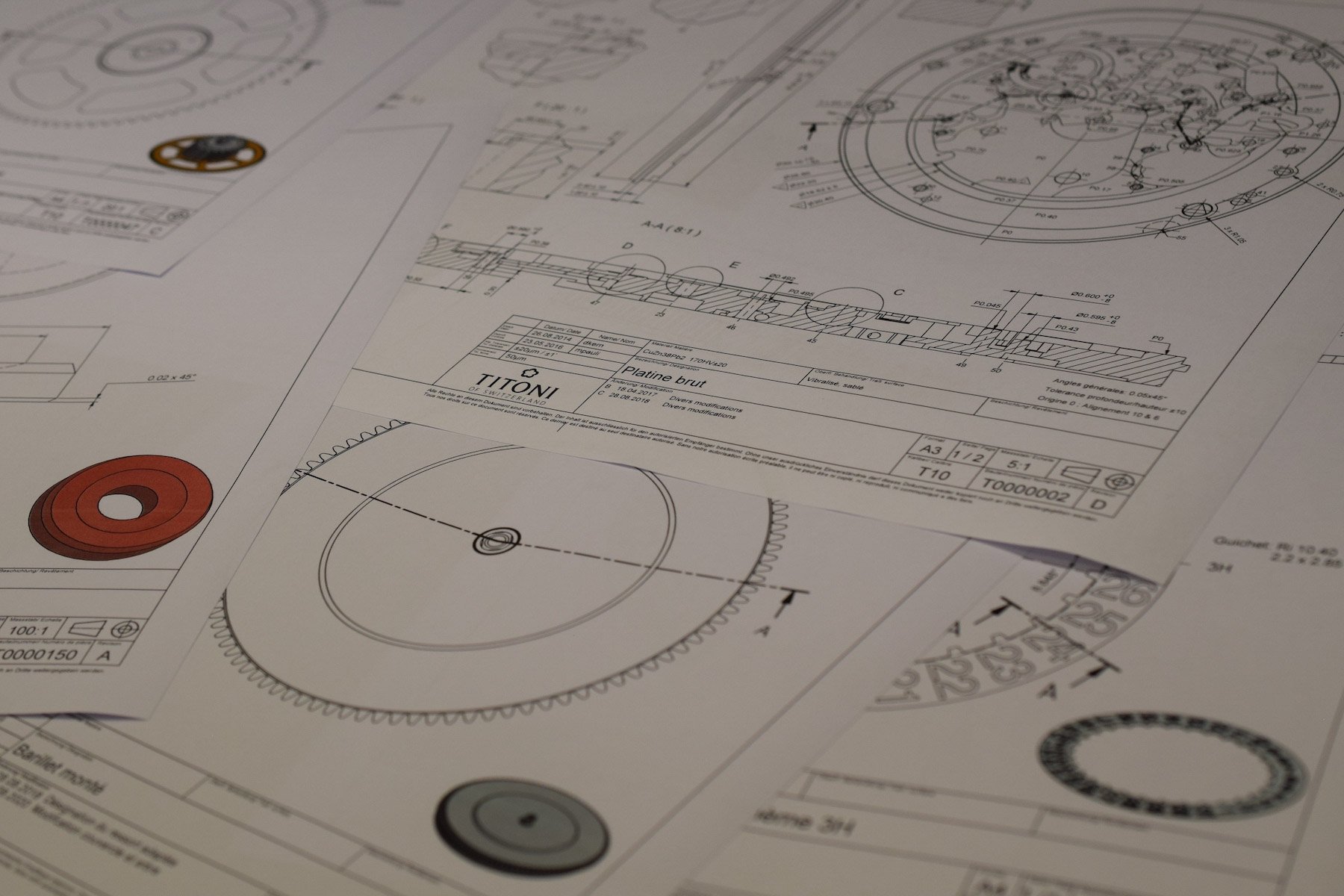

Consequently, the company whittled down a list of dozens of potential features that could be important for a movement to just three. In Titoni’s eyes, the most important things to consider were costs, quality, and movement height. These set the clear priorities of the T10-project, the name Titoni gave to its first-ever self-developed movement. The architecture of the T10 manufacture movement should be cost-effective, of excellent quality from the very outset, and as thin as possible.

The project was launched around these criteria — and they accompanied it over the entire six-year development period. The most challenging criteria was that of the costs. For Titoni’s management, it was essential that watches with the new T10 movement fit into the current Titoni price bracket. What Titoni needed first and foremost was a solid and reliable caliber without fancy features.

Copying an existing ETA movement was not an option

Titoni’s mission, with its clearly defined priorities, might sound simple and easy, but was, in reality, quite the opposite. To bring watches with a mechanical in-house movement onto international markets for less than CHF 2,000 — especially when “only” a few thousand pieces are produced per year — was an extremely ambitious goal. There are very few brands that could have done the same.

Nonetheless, the project took shape, step-by-step. Titoni knew from the very beginning that copying an existing ETA movement was not an option for the company. Not only should the new movement’s size and appearance differ from those of existing movements, but it should also fit into the dimensions of the current Titoni references such as the Master Series, Airmaster, or Cosmo King. Titoni finally chose a 13’’’ (Ø 29.30mm) dimension, which means the movement’s diameter is 15% bigger than current ETA and Sellita movements.

Running for 75 hours

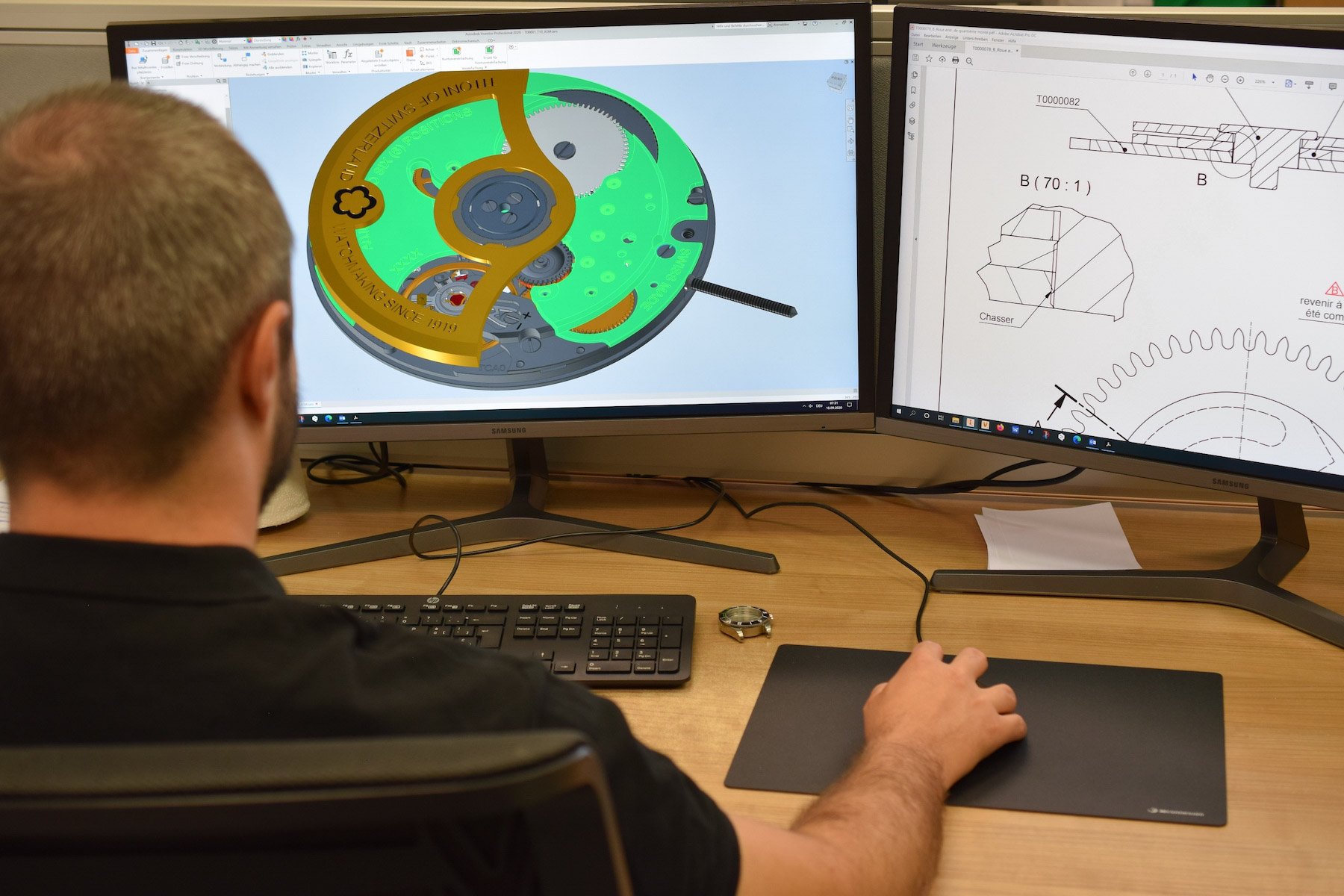

After these detailed decisions had been made, a small team of designers and watchmakers at Titoni set to work on developing and building the T10 manufacture movement. After three years of construction and collaboration with specialized suppliers from the Jura Arc and Titoni’s hometown of Grenchen, the first prototypes finally saw the light of the day. However, the journey from the first functional prototypes to reliable and robust industrial movements was very long and arduous.

In addition, Titoni’s vision included an increased power reserve. The aim was to create a movement that vastly outperformed the standard 38–42 hours one might expect from a “standard” movement. This posed another major problem. To solve this conundrum, the company performed many experiments. Thankfully, the many hours of work ultimately paid off. The T10 runs for up to 75 hours on a full-wind. It has a minimum guaranteed power reserve of 68 hours from fully wound.

Tiptoeing through a minefield

To sum up, the process of developing and producing your own mechanical watch-movement is like tiptoeing through a minefield. There are numerous pitfalls. There are plenty of things that can go wrong. Errors or bad choices made in the initial phase of such a project could cost a lot of time and money to adjust later on.

It was clear from the very outset that this movement would not be a “one-off project” for Titoni. It had to be the start of a new, long-lived internal product. Titoni invested in expensive tools at an early stage. That decision reflected the brand’s belief in the sustainability of its own mechanical movement line. A major advantage was that the T10 was industrialized at an early stage and was therefore ready for production scaling.

T10 manufacture movement

The T10 debuted in Titoni’s Line 1919, the new series launched to mark the company’s 100th anniversary. And at the end of last year, the company’s latest diver’s watch, the Seascoper 600 was fitted with a T10 official certified chronometer. The robust caliber is thus predestined to tick at the heart of future watch models in the Titoni collection. Learn more at titoni.ch.

This is a preferred position post. Learn more.